Benefits of an Induction Bar Heater for Forging

The rapid advancement of industrial technologies is continuously challenging traditional methods, opening the doors for more efficient and effective solutions. Among these modern innovations, the Induction Bar Heater stands out, providing an array of substantial benefits for forging processes. Induction bar heaters have revolutionized the forging industry, offering numerous advantages over traditional heating methods. In this article, we will explore the benefits of using induction bar heaters for forging applications. From their efficient heating capabilities to their environmentally friendly nature, induction bar heaters have become the go-to choice for modern forging processes.

1.Rapid and Precise Heating with Induction Bar Heater

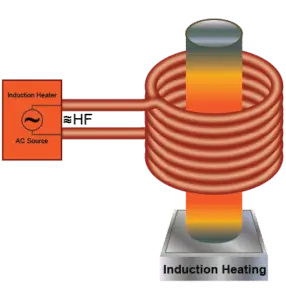

Induction bar heaters excel in providing rapid and precise heating, enabling manufacturers to achieve specific temperature profiles quickly and consistently. The induction heating process relies on electromagnetic induction, where an alternating current generates a magnetic field around the workpiece, causing it to heat up. This method ensures that the required temperature is attained precisely, minimizing material wastage and improving energy efficiency.

2.Unmatched Efficiency: The Pinnacle of Induction Bar Heater Benefits

One of the most significant benefits of Induction Bar Heater for forging is its supreme energy efficiency. Unlike traditional forging methods that waste energy in heating the surroundings, induction heaters target the material directly. This process minimizes energy loss, leading to a reduction in operational costs and a positive environmental impact. Fig. 1, shows an illustration of the traditional and modern forging methods.

3.Precision and Uniformity in Heating

The precision offered by the Induction Bar Heater is another crucial advantage. Due to the precise control of the magnetic field and current, it enables uniform heating, ensuring a consistent quality of forged components. This uniformity reduces wastage due to defects, providing a superior output.

4.Faster Heating Cycles with Enhanced Efficiency and Productivity

Induction bar heaters significantly enhance efficiency and productivity in forging operations. When compared to traditional methods, induction heating for forging provides faster heating cycles. The time to reach the required temperature is significantly lower, allowing for quicker production and higher throughput. This benefit directly translates to increased productivity and profitability. Moreover, the controlled and uniform heating process reduces the need for additional post-heating treatments, further streamlining the production process.

5.Energy Efficiency and Cost Savings

The use of induction bar heaters results in remarkable energy efficiency compared to traditional heating methods. Induction heating directly heats the workpiece without the need to heat the surrounding air, resulting in minimal heat loss. This efficiency not only reduces energy consumption but also translates into substantial cost savings for manufacturers, making induction heaters a cost-effective choice in the long run.

6.Clean and Environmentally Friendly

Induction bar heaters are an eco-conscious option for forging processes. Since they do not involve the burning of fossil fuels or the production of harmful emissions, they contribute to a cleaner and greener environment. The absence of open flames or hot surfaces also enhances the safety of the workplace, reducing the risk of accidents.

7.Consistent Heating for Uniform Results

Achieving uniform heating across the entire workpiece is crucial for high-quality forging. Induction bar heaters offer exceptional consistency in heating, ensuring that the entire length of the bar reaches the desired temperature uniformly. This consistency results in superior forging outcomes with fewer defects and rejects, ultimately enhancing the overall product quality.

8.Controlled Heating with Temperature Monitoring

Induction bar heaters are equipped with advanced temperature monitoring and control systems. These systems enable precise regulation of the heating process, allowing operators to maintain specific temperatures within narrow tolerances. With such control, the risk of overheating or underheating is minimized, preventing material damage and ensuring repeatable results.

9.Compact Design and Space Efficiency

Compared to bulky and space-consuming conventional furnaces, induction bar heaters boast a compact and space-efficient design. This feature is particularly advantageous for facilities with limited floor space. Additionally, their modular build allows for easy integration into existing forging lines, making them a versatile choice for various manufacturing setups.

Working Principle of Induction Bar Heater

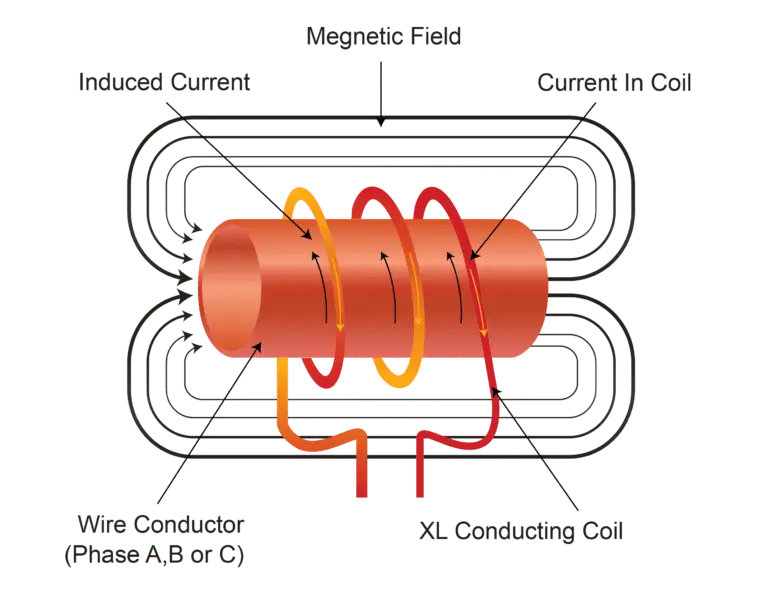

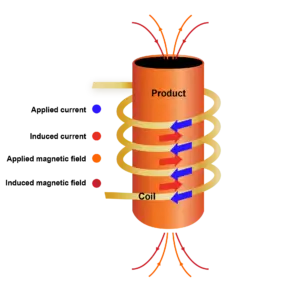

Understanding the benefits of the Induction Bar Heater is incomplete without comprehending its working principle. The working principle of an induction bar heater revolves around Faraday’s law of electromagnetic induction. When an alternating current flows through a coil, it creates a rapidly changing magnetic field. Placing a conductive workpiece, such as a metal bar, within this magnetic field induces eddy currents in the workpiece. These eddy currents generate heat, effectively heating the metal bar without direct physical contact. Fig. 3, depicts the working principle of an Induction Bar Heater.

Why Choose Induction Heater for Forging?

Given the above benefits, the Induction heater for forging stands as an invaluable tool for the modern forging industry. It:

Offers considerable energy savings.

Ensures consistent quality of output.

Provides faster production cycles.

Promotes a healthier work environment without the hazards of open flames.

Allows precise control over the forging process.

One of the salient features of the Induction heater for forging is its flameless operation. Unlike conventional methods that use an open flame, induction heating operates without fire, thus mitigating risks associated with flame-related accidents. This results in enhanced safety measures, improved workspace conditions, and overall peace of mind.

To sum up, the Induction Bar Heater for forging offers numerous benefits that make it an attractive choice for industry professionals. By choosing induction heating for forging, businesses can not only enhance their operational efficiency but also contribute positively to the environment. Thus, the transition from traditional heating methods to induction heaters is not just a smart choice; it is a necessary step towards a sustainable future.

By investing in an Induction Bar Heater, businesses can unlock new levels of productivity and cost-effectiveness. If you are in the forging industry, it’s time to consider making the switch and reaping the benefits this advanced technology has to offer.

Conclusion

The benefits of using induction bar heaters for forging are undeniable. Their ability to deliver rapid, precise, and uniform heating results in enhanced efficiency, cost savings, and improved product quality. Moreover, the eco-friendly nature of induction heating aligns with modern sustainability practices, making it an environmentally responsible choice. As manufacturers continue to seek innovative solutions to optimize their forging processes, induction bar heaters stand out as a reliable and advanced technology that caters to the demands of the industry while being mindful of the environment.

References

- Badia, A. & Alves, Jose & Bay, F. & Barlier, Julien. (2019). On the effect of boundary conditions for electromagnetism in induction heat treatment simulations. AIP Conference Proceedings. 2113. 100003. 10.1063/1.5112636.

- Durukan, Ilker. “Effects of induction heating parameters on forging billet temperature.” Master’s thesis, Middle East Technical University, 2007.

- Bobart, G. F. “Induction heating.” AccessScience (2020).

- Hawryluk, Marek, Paweł Widomski, Marcin Kaszuba, and Jakub Krawczyk. “Development of new preheating methods for hot forging tools based on industrial case studies and numerical modeling.” Metallurgical and Materials Transactions A 51 (2020): 4753-4764.

- Song, Min Churl, and Young Hoon Moon. “Coupled electromagnetic and thermal analysis of induction heating for the forging of marine crankshafts.” Applied Thermal Engineering 98 (2016): 98-109.