1. Introduction

In today’s competitive mining environment, every gram of recovered precious metal counts. Modern refineries and gold- or silver-processing plants increasingly depend on induction smelting furnaces to transform concentrates and precipitates into high-purity bullion. These systems combine electromagnetic precision with clean, fuel-free heating — producing faster melts, lower energy bills, and consistent metal quality.

At Electroheat Induction, Our advanced electric induction smelting furnaces are designed for continuous operation in tough mining environments, offering efficient melting, uniform temperature control, and safe, smoke-free performance supported worldwide by our engineering team.

Our induction furnaces for silver and gold precipitate (product of Merrill-Crowe Process or Electrowinning Process) ensure that you receive optimal metal recovery, while delivering extraordinary energy efficiency through the most advanced induction melting technologies available.

2. Induction Smelting in the Mining Industry

Induction furnaces are transforming precious metal recovery in the mining industry, offering a superior solution for smelting gold and silver, especially precipitates from processes like Merrill-Crowe or electrowinning. This advanced technology provides numerous benefits:

- Direct and Efficient Heating: Heat is generated directly within the metal, leading to rapid and even melting.

- High Purity: The flame-free process prevents contamination, ensuring pure alloys.

- Customizable Solutions: Furnaces can be customized for various metals and alloys.

- Improved Operations: Boosts throughput and enhances recovery rates.

- Optimized Gold Recovery: Advanced techniques, like in-situ iron collection, improve gold recovery from complex materials such as cyanidation tailings

3. Technical Specifications and Capacity Range

Electroheat provides a comprehensive portfolio of industrial induction smelting furnaces, ranging from compact laboratory-scale models to large-capacity units engineered to process multiple tons of material per batch.

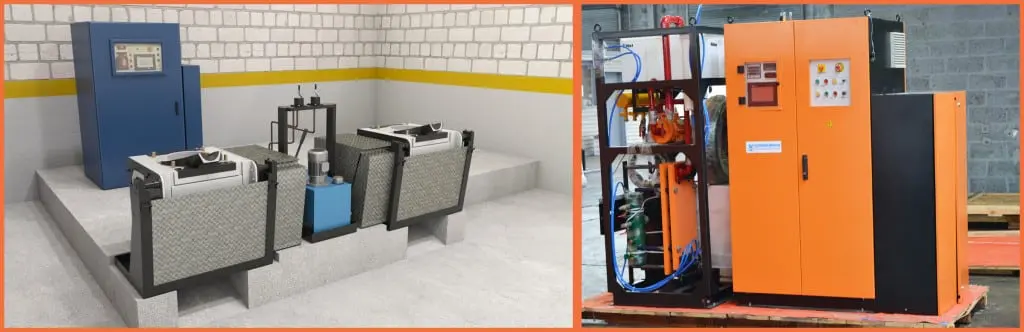

The layout below (Figure 1) illustrates a standard induction smelting configuration commonly employed in Electroheat’s mining furnace designs, showing the relationship between the power supply, coil, and crucible.

(By Electroheat).

Each furnace incorporates advanced technical features, including water-cooled copper coils, robust refractory linings, and medium-frequency power supplies designed to optimize electromagnetic stirring, thereby ensuring homogenous heating throughout the melt. This precise control over the molten bath enhances metallurgical reactions and contributes to the production of high-purity metals.

Specifications:

- Output Power Rating: 50 kW to 2000 kW

- Melting Capacity: 50 kg to 3 tons working capacity

- Application: Suitable for medium and large-sized applications

- Frequency: Medium and Low frequency depends on the application

4. Intelligent Features and Control Systems

- Real-time Monitoring: Advanced Human-Machine Interface provides instant insights into critical operational parameters like temperature, voltage, and current.

- Data-Driven Precision: Meticulously log up to 10 years of production data and track precise process parameters for unparalleled analysis.

- Remote Expertise: Secure remote diagnostics and troubleshooting via a static IP connection ensure continuous support.

- Elevated Safety: Sophisticated automation capabilities significantly enhance operational safety.

- Maximized Uptime: Minimize unscheduled downtime, ensuring continuous and reliable production.

- Repeatable Excellence: Guarantee highly consistent smelting cycles, a fundamental attribute of modern medium-frequency induction furnace designs.

5. Why Choose Induction Over Conventional Smelting

Induction technology eliminates the inefficiencies of fuel-based furnaces. It provides precise temperature control, faster melting, and zero direct emissions — all key advantages for sustainable mining.

| Feature | Induction Smelting Furnace | Conventional Fuel Furnace |

| Heating Type | Electromagnetic, clean energy | Combustion-based heat |

| Energy Efficiency | 70 – 80 % | 35 – 50 % |

| Metal Purity | High – no fuel contamination, uniform melt | Moderate – possible fuel impurities, uneven heating |

| Environmental Impact | Zero direct CO₂ or particulate emissions, quiet operation | High emissions, smoke, noise pollution |

| Process Repeatability & Data | Digital automation, precise control, data logging for consistency | Manual operation, variable control, limited data for analysis |

| Operational Safety | No open flame, reduced heat loss to surroundings, safer work environment | Open flame, high radiant heat, risks associated with fuel handling |

| Maintenance | Low – simple refractory change, fewer moving parts, increased uptime | High – frequent repairs, burner maintenance, reduced uptime |

6. Applications Across Mining and Refining

Electroheat Induction furnaces are used in key mining and refining applications:

- Gold and Silver Smelting: Efficiently smelt concentrates, particularly from Merrill-Crowe or electrowinning, ensuring high recovery yields with precise temperature control.

- Precious Metal Recovery: Recover residual metals from challenging materials like metallurgical slags and mine tailings, enhancing resource utilization.

- High-Purity Bullion Production: Produce market-ready bullion with controlled heating that minimizes contamination, meeting stringent quality standards.

These clean, energy-efficient systems help mining and refining operations achieve consistent production, comply with environmental regulations, and support sustainable practices.

7. Global Reach and Technical Support

With installations across Africa, Europe, the Middle East, and the Americas, Electroheat Induction provides full project support — from design and manufacture to commissioning and operator training. Our technical teams offer on-site service and remote diagnostics, ensuring your equipment maintains maximum uptime.

“Providing Worldwide Installation and Expert Consultation.”

8. Why Electroheat Induction

As a pioneer in IGBT-based induction technology, Electroheat delivers reliable, energy-efficient smelting solutions tailored for the mining sector. Each industrial induction smelting furnace is engineered to deliver superior heat uniformity, lower operating costs, and long service life — proven across foundries and refineries worldwide.

Electroheat furnaces are outfitted with a built-in diagnostic tool called HMI screen. Graphical display of electrical parameters provided on the control screen. Data logging facility can store up to 10 years’ data such as kW’s consumed, daily and minute wise reports. Remote web monitoring/control can be done using static IP for trouble shooting purpose.

In partnership with our clients, we combine engineering precision, sustainability, and global support to redefine metal recovery excellence.

👉 Contact us today for a free quote on a custom-designed induction smelting furnace for your mining or refining facility.

Our Videos

Watch our Videos

| Crucible Number (EX/EHM) | Outside Diameter (D) (mm) | Height (H) (mm) | Brass Capacity (Kg) | Brass Capacity (Lbs) | Brimful Capacity (Litres) | |

|---|---|---|---|---|---|---|

| EX323 | 165 | 318 | 25 | 55 | 4.3 | |

| EX1601 | 222 | 470 | 60 | 132 | 10 | |

| EX447 | 254 | 400 | 75 | 165 | 13 | |

| EX444 | 254 | 475 | 90 | 200 | 15 | |

| EX552 | 295 | 450 | 114 | 250 | 20 | |

| EX329 | 330 | 530 | 148 | 325 | 25 | |

| EX330 | 330 | 635 | 183 | 402 | 31 | |

| EX390 | 362 | 508 | 178 | 392 | 30 | |

| EX185 | 390 | 460 | 185 | 407 | 31 | |

| EX187 | 390 | 535 | 218 | 480 | 37 | |

| EX181 | 390 | 632 | 260 | 572 | 44 | |

| EX702 | 445 | 635 | 359 | 790 | 61 | |

| EX703 | 445 | 585 | 329 | 724 | 56 | |

| EX71 | 445 | 660 | 374 | 823 | 64 | |

| EX70 | 445 | 762 | 435 | 957 | 74 | |

| EX722 | 500 | 560 | 371 | 816 | 64 | |

| EX72 | 500 | 775 | 540 | 1188 | 92 | |

| EX75 | 530 | 650 | 524 | 1153 | 90 | |

| EX572 | 570 | 710 | 683 | 1502 | 117 | |

| EX573 | 570 | 755 | 729 | 1604 | 125 | |

| EX574 | 570 | 825 | 801 | 1762 | 137 | |

| EX575 | 570 | 865 | 842 | 1852 | 144 | |

| EX576 | 570 | 890 | 867 | 1907 | 148 | |

| EX571 | 570 | 900 | 878 | 1931 | 150 | |

| EX570 | 570 | 1000 | 980 | 2156 | 168 | |

| EX650 | 645 | 1000 | 1072 | 2358 | 183 | |

| EX651 | 649 | 1150 | 1272 | 2798 | 217 | |

| EX652 | 650 | 1190 | 1327 | 2919 | 227 | |

| EX800 | 800 | 1100 | 2199 | 4838 | 376 | |

| EX860 | 800 | 600 | 1152 | 2534 | 196 | |

| EX875 | 800 | 750 | 1466 | 3225 | 250 | |

| EX905 | 905 | 1100 | 3115 | 6853 | 533 |

- All above crucibles can be supply with spout upon request.

- Wall thickness of the crucible vary from size to size of the crucible. Wall thickness will be approx. 25 mm for small crucible and 45 mm for large size crucible. Contact us for more information.

We provide Silicon Carbide and Graphite Crucible. Contact us for quote.