Why Use Induction Furnaces for the Smelting of Precious Metals

The world of precious metals is a fascinating sphere, where the transformation of raw materials into

valuable items is an art form. One of the core processes in this journey is smelting – the extraction of precious metals from their ores. This piece explores the question: What is the best method for smelting precious metals?. The answer to this problem can be described using two words “Induction furnaces”.

Induction furnaces have emerged as the most widely opted choice for smelting precious metals due to their unique advantages and superior technical capabilities. In this article, we will explore the reasons behind the popularity of induction furnaces for smelting precious metals, the types of materials that can be smelted, their applications, and the technical details that make them the best option for this critical process.

1. Understanding Induction Furnaces

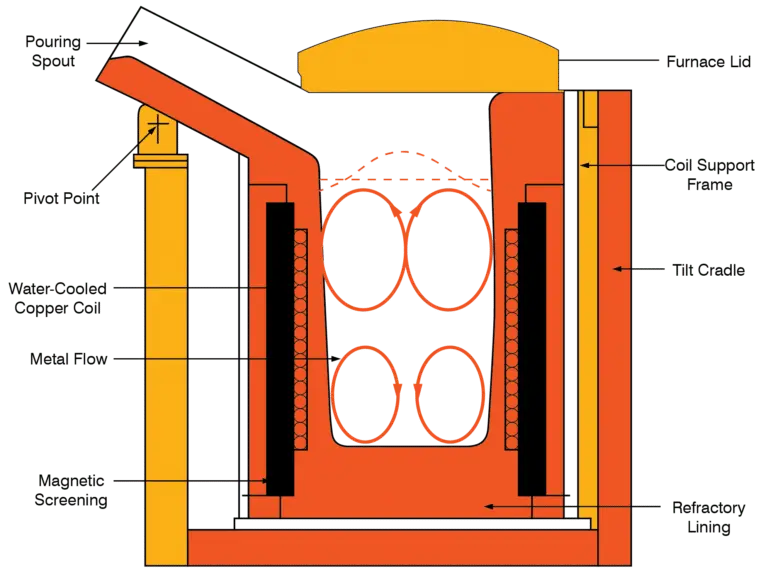

Induction furnaces are advanced metallurgical tools that utilize electromagnetic induction to generate heat within a conductive material, such as precious metals like gold, silver, platinum, and others. The furnace consists of a crucible, which holds the metal to be melted, and an induction coil, which generates a fluctuating magnetic field. This field induces electric currents within the conductive material, leading to resistive heating and rapid temperature rise. The metal within the crucible begins to melt at a controlled rate, facilitating the separation of impurities and producing high-quality, refined precious metals. Fig. 1, shows a schematic diagram of a typical induction furnace. Induction furnaces play a crucial role in the smelting process, forming an integral part of precious metal melting equipment. They help separate precious metals from impurities, ensuring the extraction of high-quality metal.

Metal

an Induction melting

2. Induction Furnaces: Unique Smelting Solution

Smelting is the transformative process that harnesses the power of heat to extract and refine precious metals from their ores, and induction furnaces have revolutionized this ancient technique with their innovative and efficient approach. Fig. 2, shows a still of an industrial smelting process.

The uniqueness of induction furnaces lies in their application of electromagnetic principles. Unlike traditional smelting techniques that employ direct flame or open heat sources, induction furnaces generate heat through electromagnetic fields. They offer a wealth of benefits that make them the preferred choice for smelting precious metals:

Efficiency: Induction furnaces can reach incredibly high temperatures, ensuring efficient smelting of precious metals. Their rapid heating and cooling capability minimizes the waste, enhancing overall efficiency.

Precise Temperature Control: These furnaces allow for precise temperature regulation, ensuring consistent smelting results and minimal material wastage.

Environmentally Friendly: The operation of induction furnaces doesn’t involve burning fossil fuels. Therefore, they have a much smaller carbon footprint compared to traditional methods.

Applicability to Various Metals: They can be used for the smelting of various precious metals such as gold, silver, ruthenium, platinum, iridium, rhodium, and osmium. This wide range of usability boosts their demand in numerous industries.

Precision Control: Unlike traditional furnaces, induction furnaces offer precision control over the melting process. This allows for higher-quality end products, ensuring the purity and value of the precious metals are retained.

Safety: The design of induction furnaces eliminates the need for direct contact with the heat source, resulting in a safer environment for operators.

Durability: With minimal moving parts, induction furnaces are highly durable and require less maintenance, resulting in lower long-term costs.

Cost-effectiveness: They are known for their energy efficiency, translating into cost savings over time.

3. Types of Materials that Can be Smelted:

Induction furnaces demonstrate exceptional adaptability in smelting a wide range of precious metals, including:

Gold: The smelting of gold is a crucial process in the jewelry and electronics industries. Induction furnaces’ precise temperature control ensures high purity and quality of the gold output.

Silver: Smelting silver demands a controlled environment to prevent oxidation and impurity absorption. Induction furnaces offer a clean and inert atmosphere, resulting in high-grade silver output.

Platinum Group Metals (PGMs): Induction furnaces are the preferred choice for smelting PGMs like platinum, iridium, rhodium, and osmium, which are widely used in catalysts and medical equipment due to their unique properties.

4. Applications of Induction Furnaces for Smelting Precious Metals:

Jewelry Industry: Induction furnaces are extensively used to smelt gold and silver for jewelry manufacturing, ensuring impeccable purity and enhancing the metal’s value.

Electronics and Electrical Industries: The demand for precious metals like gold and silver in electronic components necessitates efficient and reliable smelting processes provided by induction furnaces.

Refining and Recycling: Induction furnaces play a vital role in the refining and recycling of precious metals, minimizing waste and maximizing resource utilization.

5. Advantages Over Other Techniques:

Induction furnace crucibles are made from specialized materials like graphite and ceramics, which can withstand high temperatures and chemical reactions. These crucibles play a vital role in maintaining the purity of the melted precious metals. Also, induction furnaces provide a controlled environment with low oxygen levels, preventing metal oxidation during the smelting process. This ensures the preservation of metal purity, crucial for applications that require ultra-high-grade materials. Some of the distinct advantages of why use induction furnaces for smelting of precious metals can be summarized as:

Better Quality Melts: Induction heating offers excellent metallurgical control, leading to higher quality melts.

Extended Furnace Lifespan: Induction furnaces usually have a longer lifespan compared to fuel-fired furnaces, reducing replacement and maintenance costs.

Rapid Heating: Induction furnaces offer quick heating rates, reducing processing time and increasing productivity.

Uniform Heating: The induction process ensures even heating throughout the material, preventing localized overheating or uneven mixing.

Reduced Energy Consumption: Their high efficiency translates to lower energy consumption, resulting in cost savings for operators.

Conclusion

Induction furnaces have proven to be a game-changer in the smelting of precious metals. With their advanced technology, energy efficiency, precise temperature control, and reduced metal contamination, they offer unparalleled advantages over traditional melting methods. Their ability to accommodate a diverse range of materials and applications makes them indispensable in the jewelry, electronics, and refining industries. By harnessing electromagnetic induction, these furnaces provide a clean and green solution, delivering high-quality, refined precious metals that cater to the demands of modern industries.

In a world striving for sustainability, induction furnaces offer a solution that combines efficiency, quality, and ecological responsibility. The question isn’t just “why use induction furnaces”, but rather “why aren’t you already using one?” With these facts in mind, it’s time to act, upgrade your precious metal melting equipment’s and opt for induction furnaces for a better, more productive smelting process.

References:

1. Parga, J. R., G. G. Muzquiz, J. L. Valenzuela, and F. K. Ojebuoboh. “Recycling lead to recover refractory precious metals.” JOM 53 (2001): 19-21.

2. Hoffmann, James E. “Recovering precious metals from electronic scrap.” Jom 44 (1992): 43-48.

3. Xiao, Songwen, Guoxing Ren, Meiqiu Xie, Bing Pan, Youqi Fan, Fenggang Wang, and Xing Xia. “Recovery of valuable metals from spent lithium-ion batteries by smelting reduction process based on MnO–SiO 2–Al 2 O 3 slag system.” Journal of Sustainable Metallurgy 3 (2017): 703-710.

4. Lavrov, Sergey. “Smelting induction furnace for metal, diagram, properties of types. Homemade induction furnace for melting metal Homemade induction furnace for melting metals.”