How to Melt Aluminum using Induction

Introduction

Aluminum is one of the most widely used metals in the world. From car parts to construction materials, its lightweight strength makes it invaluable. Just as important, aluminum can be recycled endlessly without losing quality. To recycle or process aluminum, industries need furnaces that are efficient, clean, and safe. That is where an induction aluminum melting furnace comes in. Electroheat Induction, leveraging its pioneering expertise in Insulated Gate Bipolar Transistor technology, provides sophisticated global solutions for aluminum melting.

Specifications:

- Output Power Rating: 50 kW to 10.000 kW

- Melting Capacity: 50 kg to 10 tons working capacity

- Application: Suitable for medium and large-sized applications

- Frequency: Medium and Low frequency depends on the application

Why Induction for Aluminum Melting?

Melting aluminum with an induction furnace offers distinct advantages over traditional gas or oil-fired systems, making it the superior choice. Here’s a breakdown of why:

- Unrivaled Precision: Aluminum’s relatively low melting point of approximately 660 °C demands meticulous temperature management. Induction furnaces provide operators with unparalleled control, allowing for exact adjustments that prevent overheating and significantly reduce oxidation, ultimately preserving the quality and integrity of the metal.

- Exceptional Efficiency: By directly applying energy to the metal through electromagnetic induction, induction furnaces minimize energy loss. This direct heating method ensures that virtually all energy is utilized for melting, leading to a highly efficient and cost-effective operation.

- Environmentally Superior and Cleaner Output: The absence of combustion in induction melting means no harmful gases or residues are produced. This not only results in a dramatically cleaner process, benefiting both the environment and workplace safety, but also yields a higher-quality aluminum product free from combustion-related impurities.

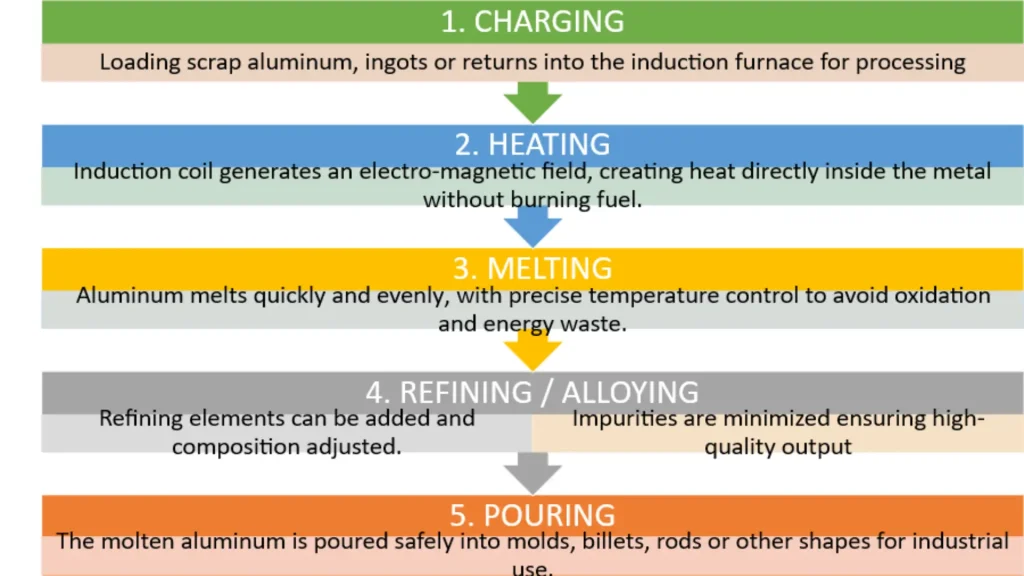

The Induction Aluminum Melting Process

The induction aluminum melting process employs electromagnetic induction for direct heating, facilitating rapid, consistent, and highly efficient melting. This method is particularly advantageous for processing scrap aluminum and its alloys, which are increasingly utilized in industries like automotive and aerospace due to their favorable strength-to-weight ratio, necessitating efficient and precise melting to maintain material integrity [1]. By curtailing energy expenditure, this process demands only 2.8 kWh/kg and emits 0.6 kg CO2/kg for secondary production, a stark contrast to primary aluminum production’s 45 kWh/kg and 12 kg CO2/kg emissions [2]. The subsequent steps detail the methodology, from initial charging to final pouring, while upholding stringent standards of quality, energy efficiency, and operational safety.

Advantages of Induction Aluminum Melting

1. Energy Benefits (EBs)

Induction furnaces use less energy per ton of aluminum compared to fuel-fired furnaces. Medium-frequency induction systems achieve high efficiency and fast melt rates, saving operating costs.

2. Non-Energy Benefits (NEBs)

Induction furnaces offer significant NEBs that go beyond just energy savings:

- Improved product quality – fewer impurities and less oxidation mean cleaner aluminum.

- Environmental gains – no combustion gases, reduced CO₂, and safer working conditions.

- Reduced maintenance – fewer moving parts, no burners, and lower wear-and-tear reduce downtime.

- Safer operations – no open flames, no fuel handling, and reduced workplace hazards.

- Increased productivity – faster cycle times and consistent performance improve output.

3. Cost Savings

Less energy, lower maintenance, and reduced scrap loss translate into measurable financial benefits. Over time, this makes induction the most cost-effective solution for aluminum melting.

Types of Scrap That Can Be Melted

Induction furnaces are highly versatile and can efficiently process a wide range of aluminum scrap materials, including:

- Aluminum scrap – cans, cuttings, and industrial returns.

- Cast aluminum parts – automotive and machinery components.

- Mixed aluminum alloys – refined into billets and ingots with precise composition control.

An induction melter for aluminum scrap can handle all of these efficiently, supporting recycling industries and manufacturers alike. This adaptability extends to various forms of aluminum waste, offering a sustainable solution for resource recovery and minimizing environmental impact. The incorporation of recycled aluminum not only reduces the overall cost of production but also preserves raw materials.

Medium Frequency Induction Aluminum Melting

Medium frequency furnaces are the most common choice for aluminum. They provide:

- Rapid heating with deep penetration.

- Adjustable power settings for different scrap or alloy types.

- Stable, repeatable performance, which is vital for large-scale recycling plants.

Electroheat Induction offers induction aluminum melting furnaces designed for both small foundries and large industrial operations.

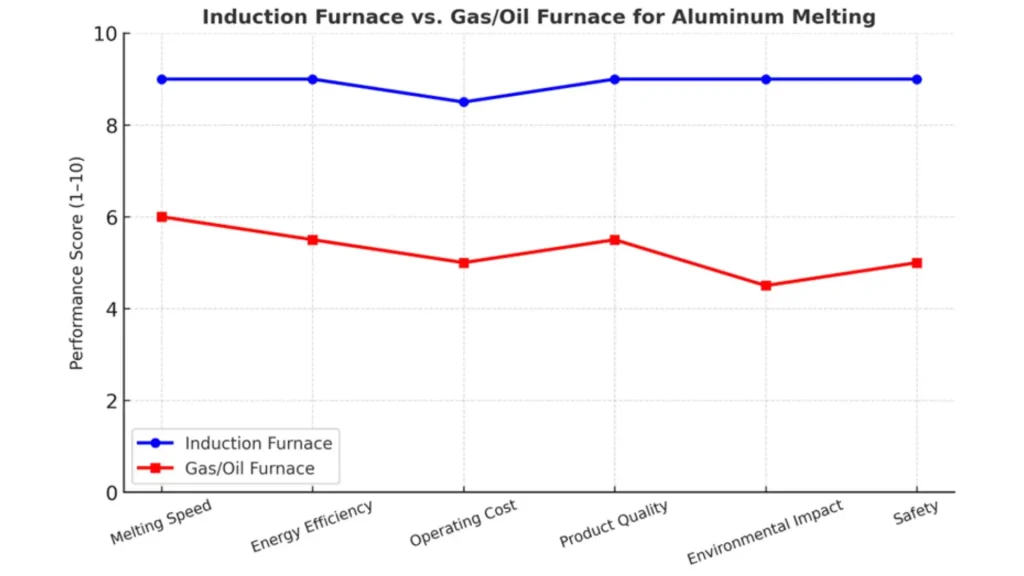

Induction vs. Gas/Oil Furnace for Aluminum Melting

Before choosing a furnace, industries often compare induction with older fuel-based systems. The table below shows the key differences:

| Feature | Induction Furnace | Gas/Oil Furnace |

| Melting Speed | Fast, even heating | Slower, uneven |

| Energy Efficiency | High – minimal energy loss | Lower – fuel wasted |

| Operating Cost | Lower (electricity-based) | Higher (fuel costs, maintenance) |

| Product Quality (NEB) | Cleaner melt, fewer impurities | More oxidation, lower quality |

| Environmental Impact | No combustion gases, lower CO₂ | Emissions, pollution |

| Safety (NEB) | Safer, no open flames | Higher risk, fuel handling required |

Performance Comparison Chart

Complementing the tabular data, the subsequent chart visually demonstrates the superior performance of induction furnaces over traditional gas/oil systems across critical metrics, including energy efficiency, product quality, and operational safety. This comprehensive comparison elucidates the rationale behind the global adoption of induction technology across various industries. The increasing demand for electrical energy across various industrial sectors, coupled with the need to mitigate greenhouse gas emissions, further underscores the strategic importance of adopting energy-efficient technologies like induction melting

shows induction furnaces achieving higher scores across all performance measures, confirming both

energy and non-energy benefits.

Why Electroheat Induction

Electroheat Induction combines experience, advanced technology, and worldwide support to provide the best aluminum melting solutions. Our strengths include:

- Worldwide installation and support

- Customized furnaces for aluminum recycling and alloying

- Advance and Efficient IGBT technology for reliable operation

- Expert advisory and consultation for energy and process optimization

👉 Contact us today to learn more about our induction aluminum melting furnaces and how they can improve your recycling and production processes.