How Induction Furnaces Help Gold Mining Companies

Are you a gold mining company owner or a C-level executive, looking for the most efficient and cost-effective way to melt your company’s gold ore? Hands down, induction furnaces are your best bet.

Induction furnaces have become the go-to solution for many gold mining companies due to their higher efficiency, melting speed, and environmentally friendly feature.

In this article we will discuss how induction furnaces can help make your gold mining operations more successful, saving you hours of melting your ore by using a run-of-the-mill furnace instead of doing it in a few minutes.

The main benefits of using an induction furnace over traditional ones are:

Its ability to precisely control the temperature during each phase of the casting process allows you to ensure the highest quality result from start to finish.

By taking just a few minutes to melt a load, your business will be much more profitable compared to common fuel-fired furnaces where you have to wait hours to continue the process. Thus, the amount of melted material can grow exponentially, and with it your profits.

Another great benefit offered by these machines is their environmental friendliness; since they:

do not require combustible fuels like coal or oil,

reduce drastically emissions from production processes

are perfect for businesses looking into reducing their carbon footprint as part of sustainability initiatives.

Spotless process, with no:

material contamination

direct contact between the heating element and metal being melted down. This is especially valuable when it comes to precious ore, making it ideal for use by those who

need fast results without any potential damage that can occur during operation.

The fully automatic control of the process due to the electronic technology employed, allows uniform and predictable results, without variations between batches, and is human error-proof, which makes it even more profitable to have this foundry technology.

| Feature | Induction Furnace | Traditional Furnace |

| Fuel | Electricity | Gas or diesel |

| Emissions | None | Harmful pollutants |

| Efficiency | More efficient | Less efficient |

| Speed | Faster | Slower |

| Safety | Safer | Less safe |

When it comes to coreless inductionnaces, which are the most suitable for melting gold, it is common to mention that higher frequencies are needed for load capacities of a few kilograms

As a rule of thumb, the smaller the volume of the melts, the higher the frequency of the furnace used.

Well, previously we have already clarified what this frequency consists of, but: why do we need high frequencies to effectively melt loads of gold of kilograms or a few tens of kilograms?

The answer lies in the penetration or depth of the eddy currents that circulate through the mass to be melted, and in the behavior of alternating current at high frequencies.

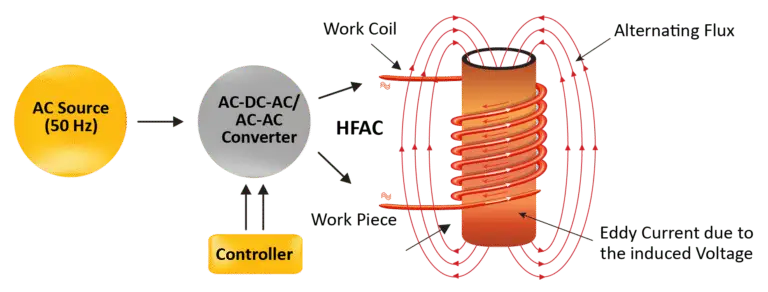

For there to be induction of voltages and currents in the load deposited in the crucible, it is necessary to feed the inductor coil that surrounds the crucible with an AC voltage.

If we fed this coil with DC voltage, no matter how high that voltage was, there would be no induction in the charge of the crucible and it would remain at room temperature.

Alternating current has the property of not being distributed uniformly through the conductive material through which it flows unless the frequency is very low.

At high frequencies, it circulates only on the surface of the conductor, so the eddy currents are concentrated closer to the surface of the load, which is more efficient for heating small melts.