Channel Induction Furnace vs. Coreless Induction Furnace: What’s the Difference?

When it comes to melting metals, there are two main types of induction furnaces: channel induction furnaces and coreless induction furnaces. Both types of furnaces offer unique advantages and disadvantages, making them suitable for different types of metals and applications.

A channel induction furnace is best for metals which have lower melting points, while the coreless furnace is best utilized for metals with higher melting points. The coreless induction furnace is capable of melting the most difficult metals such as cast iron and stainless steel. The channel induction furnace, on the other hand, is better suited for melting metals like aluminum and copper.

In terms of design, the main difference between the two furnaces lies in the shape of the induction coil. A channel furnace has a channel-shaped coil that runs around the perimeter of the furnace, while a coreless furnace has a coil that is wrapped around a crucible that holds the molten metal. The table below summarizes the main differences between the two types of induction furnaces:

| Coreless Induction Furnace | Coreless Induction Furnace |

| Best for metals with lower melting points | Best for metals with higher melting points |

| Induction heating takes place in a narrow channel at the bottom of the furnace | Induction heating takes place around a crucible that holds the molten metal |

| Suitable for melting metals like aluminum and copper | Capable of melting difficult metals like cast iron and stainless steel |

Overview of Induction Furnaces

What is an Induction Furnace?

Induction furnaces are electrically powered furnaces that use electromagnetic induction to heat and melt metal. They are commonly used in the foundry industry to melt and cast metals such as iron, steel, copper, aluminum, and precious metals.

Induction furnaces come in two main varieties: coreless and channel. Coreless induction furnaces are used for melting and holding metals, while channel induction furnaces are used for pouring and casting metals.

How do Induction Furnaces Work?

Induction furnaces work by passing an alternating current through a coil of copper tubing, creating a magnetic field. When metal is placed

inside the coil, the magnetic field induces electrical currents, or eddy currents, within the metal. These eddy currents produce heat, which melts the metal.

Coreless induction furnaces do not have a core, allowing for a larger melting chamber and more efficient melting. Channel induction furnaces have a core and a narrow channel through which the metal is poured, allowing for precise pouring and casting.

Overall, induction furnaces are a highly efficient and effective way to melt and cast metals. They offer precise temperature control, reduced energy consumption, and minimal waste.

Channel Induction Furnace

What is a Channel Induction Furnace?

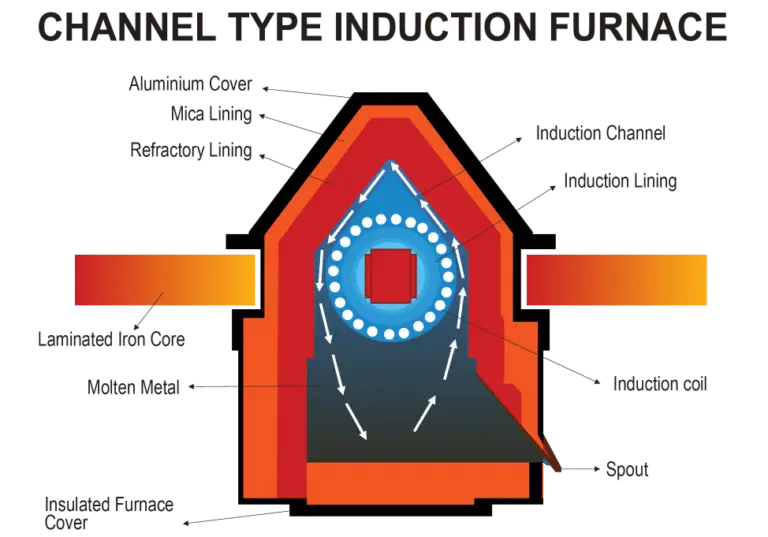

A channel induction furnace is a type of induction furnace that uses induction heating to melt metals. In this type of furnace, the induction heating takes place in a relatively small and narrow area at the bottom of the bath, known as the channel. The channel passes through a laminated steel core and around the coil assembly. The electric circuit is completed when the channel is filled with molten metal.

Advantages of a Channel Induction Furnace

There are several advantages of using a channel induction furnace:

- Efficient melting: Since the induction heating takes place in a small and narrow area, the channel induction furnace is more efficient at melting metals than other types of furnaces.

- Lower capital costs: Compared to a coreless induction furnace, a channel induction furnace requires lower capital costs, making it a good choice for small and medium-sized foundries.

- Good for low melting point metals: A channel induction furnace is best suited for metals that have lower melting points, such as aluminum, copper, and brass.

Disadvantages of a Channel Induction Furnace

Despite its advantages, there are also some disadvantages to using a channel induction furnace:

- Not suitable for high melting point metals: A channel induction furnace is not suitable for metals with higher melting points, such as cast iron and stainless steel.

- Limited flexibility: A channel induction furnace is less flexible than a coreless induction furnace since it cannot be emptied to handle alloy changes on short notice.

- Energy-wasting off-shift holding: A channel induction furnace requires energy-wasting off-shift holding, which can increase operating costs.

In summary, a channel induction furnace is an efficient and cost-effective option for melting low melting point metals. However, it is not suitable for high melting point metals and has limited flexibility.

Coreless Induction Furnace

What is a Coreless Induction Furnace?

A coreless induction furnace is a type of furnace that uses induction heating to melt metals. In a coreless furnace, the entire bath functions as the induction heating area. This means that the furnace does not have a core made of iron or other magnetic materials. Instead, the furnace uses a coil to generate a magnetic field that induces an electrical current in the metal, causing it to heat up and melt.

Advantages of a Coreless Induction Furnace

There are several advantages of using a coreless induction furnace, including:

Lower capital and installation costs: Compared to a channel holding furnace, a coreless induction furnace requires significantly lower capital and installation costs.

High productivity: Coreless induction furnaces are capable of melting large quantities of metal quickly and efficiently.

Maximum alloy flexibility: Coreless induction furnaces allow for a wide range of alloys to be melted, making them highly flexible.

Disadvantages of a Coreless Induction Furnace

While there are many advantages to using a coreless induction furnace, there are also some disadvantages, including:

- Higher energy consumption: Coreless induction furnaces require more energy than other types of furnaces, which can lead to higher operating costs.

- Limited temperature control: Coreless induction furnaces can be difficult to control, which can make it challenging to achieve precise temperature control.

- Higher maintenance costs: Coreless induction furnaces require more maintenance than other types of furnaces, which can lead to higher maintenance costs over time.

In summary, coreless induction furnaces are a highly productive and flexible type of furnace that is capable of melting a wide range of alloys quickly and efficiently. While there are some disadvantages to using a coreless induction furnace, these are generally outweighed by the benefits, making them a popular choice for many industrial applications.

Conclusion

In conclusion, both channel induction furnaces and coreless induction furnaces have their advantages and disadvantages. Depending on the type of metal being melted, one type of furnace may be more suitable than the other.

Channel induction furnaces are best for metals with lower melting points, while coreless induction furnaces are better suited for metals with higher melting points. Channel furnaces are also more energy efficient and have lower operating costs than coreless furnaces. However, coreless furnaces are capable of melting more difficult metals such as cast iron and stainless steel.

In terms of cost, channel induction furnaces are generally less expensive than coreless furnaces, but they have a smaller capacity and are not suitable for large-scale operations. Coreless furnaces, on the other hand, have a larger capacity and are more suitable for larger operations, but they are more expensive to operate and maintain.

Overall, the choice between a channel induction furnace and a coreless induction furnace depends on the specific needs of the operation. It is important to consider factors such as the type of metal being melted, energy efficiency, maintenance requirements, and cost when making a decision.