Benefits of coreless induction furnace to steel plant

In this article, we shall learn about the major benefits of coreless induction furnace for melting and smelting metal. But before going to discuss the benefits of coreless induction furnace, let us first briefly discuss the basics of coreless induction furnace.

What is a Coreless Induction Furnace?

A type of induction furnace that does not have a core within it and utilizes electromagnetic induction effect to heat and melt the charge/metal workpiece is referred to as a coreless induction furnace.

The coreless induction furnace is a kind of high-frequency induction furnace. The coreless induction furnace operates on the principle of mutual inductance (a type of electromagnetic induction effect) which is same as the principle of electrical transformer used in electrical power systems to change the voltage levels.

Construction of a Coreless Induction Furnace

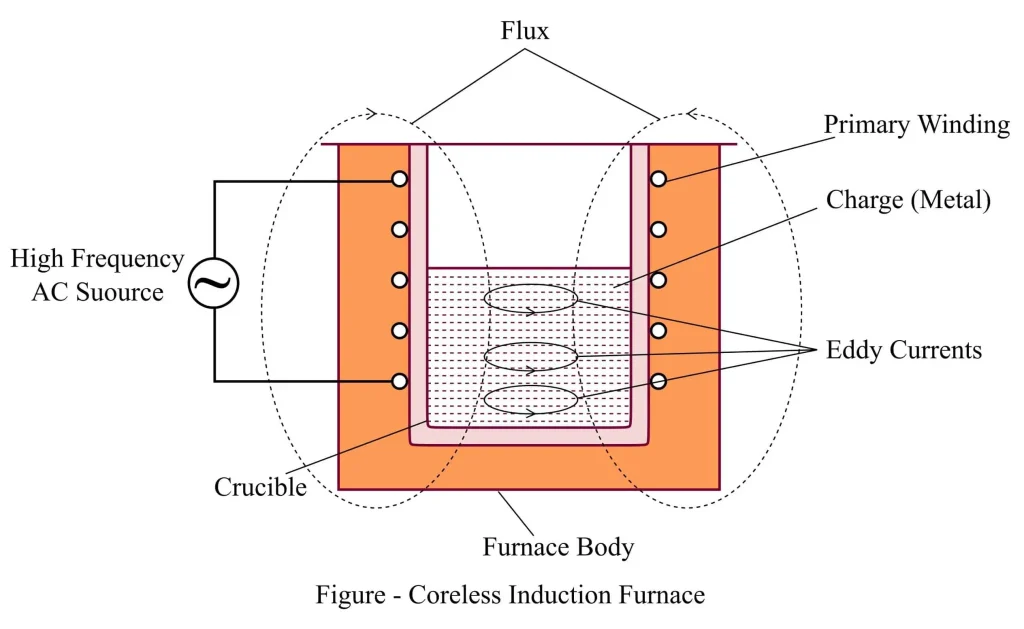

The construction of a coreless induction furnace is quite simple as it does not consist any core. The construction of a coreless induction furnace is depicted in the following figure.

The coreless induction furnace is made of ceramic in the crucible cylindrical shape as shown in the above figure. The ceramic crucible is surrounded by metallic coils made up of copper. When the coreless induction furnace is compared with an electrical transformer, then these coils serve as primary windings of the electrical transformer.

In the coreless induction furnace, the charge or metal workpiece which is to be heated is placed in the ceramic crucible, this serves as the secondary winding of the electrical transformer.

Working of Coreless Induction Furnace

Now, let us briefly discuss the operation of coreless induction furnace.

When a high-frequency AC supply is connected to the primary winding of the coreless induction furnace, an alternating flux is produced around the winding. This alternating magnetic flux links with the charge to be heated kept inside the crucible.

Due to this alternating flux, circulating currents (also called eddy currents) are induced in the body of the charge, as per the electromagnetic induction. Eddy currents induced cause heating of the charge due to its electrical resistance. This way, a charge is heated in a coreless induction furnace.

In coreless induction furnace, the flux density is low due to absence of the magnetic core in the furnace. Therefore, to compensate the effect of low magnetic flux density, high-frequency AC supply is used. However, due to high-frequency of AC, the skin effect is high which results in high copper loss in the primary winding.

Therefore, to control the temperature of primary windings some artificial cooling practices are employed. For example, for proper cooling of the primary winding, the coils are made of hollow copper tubes instead of solid copper conductors, and the cooling water be made to circulate through these tubes.

After getting a brief overview of coreless induction furnace, let us now discuss major advantages/benefits of coreless induction furnaces for melting and smelting metals.

Benefits of Coreless Induction Furnaces for Melting and Smelting Metal

Due to several benefits of coreless induction furnace, they are widely being used in melting and smelting applications. Some of the major benefits of coreless induction furnace for melting and smelting of metals are described below.

(1). Coreless induction furnaces provide stirring of molten metals:

Another important advantage of coreless induction furnaces is stirring of molten metal. Stirring helps in achieving homogeneous temperature, enhancing chemical actions, removing impurities, etc. Therefore, stirring is important for producing a high-quality final product. In coreless induction heating, there are two types of stirring methods commonly used namely, magnetic stirring and mechanical stirring.

(2). Coreless induction furnaces have high melting efficiency:

Coreless induction furnaces are capable of generating a high intensity electromagnetic field. This intense electromagnetic field can induce a high electric current (eddy current) within the body of the metal charge to be heated or melted. Consequently, it results in faster and efficient heating and melting of the metal. This way, coreless induction furnaces are highly efficient in terms of melting of charge. Because of the high melting efficiency, the coreless induction furnaces are better suited to use for melting and smelting metals to melt large volume of metal quickly and with minimum energy consumption.

(3). Coreless induction furnaces have better temperature control:

A coreless induction furnace can be equipped with an advanced temperature control system to monitor and regulate the temperature in real-time with high precision. Therefore, the coreless induction furnace allows metal charges to be melted at the desired temperature without the risk of overheating, making it suitable for melting and smelting metal. Hence, the better temperature control is another benefit of coreless induction furnace for metal processing companies.

(4). Coreless induction furnaces have low maintenance cost:

In comparison to other types of furnaces used in metal processing companies, the coreless induction furnaces require less maintenance and hence lower maintenance cost. This reduces the overall maintenance cost for melting and smelting metal.

The low maintenance cost of coreless induction furnace is mainly due to simple design and construction, lesser number of moving components, etc.

(5). Coreless induction furnaces have longer life span:

Due to a lesser number of moving parts and simple construction, the coreless induction furnaces have less wear and tear, and hence operates for a longer period of time.

(6). Coreless induction furnaces yield low emission:

As the coreless induction furnaces works on induction heating technology, and do not involve combustion of fossil fuels. Thus, coreless induction furnaces produce low emission of pollutants. Due to this reason, they are quite environment friendly to use for melting and smelting metals.

(7). Coreless induction furnaces reduce the noise pollution:

Due to quite operation, the coreless induction furnaces reduce noise pollution for melting and smelting metals. This results in reduced negative effects due to noise on the workers’ health.

(8). Coreless induction furnaces increase safety:

Coreless induction furnaces do not involve the combustion of any kind of fuel; hence they provide a safer operating environment for melting and smelting metal. Also, the automatic temperature control system eliminates the issue of overheating and risk of fire and explosion.

(9). Coreless induction furnaces enhance the quality of metal:

Coreless induction furnaces provide a precise temperature control which ensures the desired quality of metals. Hence, the use of coreless induction furnace for melting and smelting metals improves the quality of the final metal product.

(10). Coreless induction furnaces provide better utilization of metal scrap:

Coreless induction furnaces are quite efficient in metal scrap melting. This practice reduces the waste and increases the utilization of scrap metal.

(11). Coreless induction furnaces reduce the overall cost of metal production:

Coreless induction furnaces are able to melt many types of raw material without the need of expensive additives and alloys. Thus, this helps in reducing the overall production cost of the metal.

Conclusion

In conclusion, this is all about the coreless induction furnace and the significant benefits of coreless induction furnace for melting and smelting metals. As we discussed in the above sections, coreless induction furnaces offer several advantages for melting and smelting metals, such as high reliability, simpler design, easy installation and operation, no or very low maintenance cost and down time, lower energy consumption, significantly longer lifespan. All these benefits of coreless induction furnaces make them better selection for melting and smelting metals.