Preventing Power Loss in Induction billet and bar heating

Induction heating has become an indispensable process in various industries, including the manufacturing of bill ets and bars. However,power loss during induction heating can significantly impact efficiency and productivity. In this article, we will explore effective strategies and techniques to prevent power loss in induction billet and bar heating, ensuring optimal performance and cost-effectiveness. We will delve into the working principles of induction heating units and discuss practical solutions to mitigate power loss.

I.Understanding Induction Billet and Bar Heating

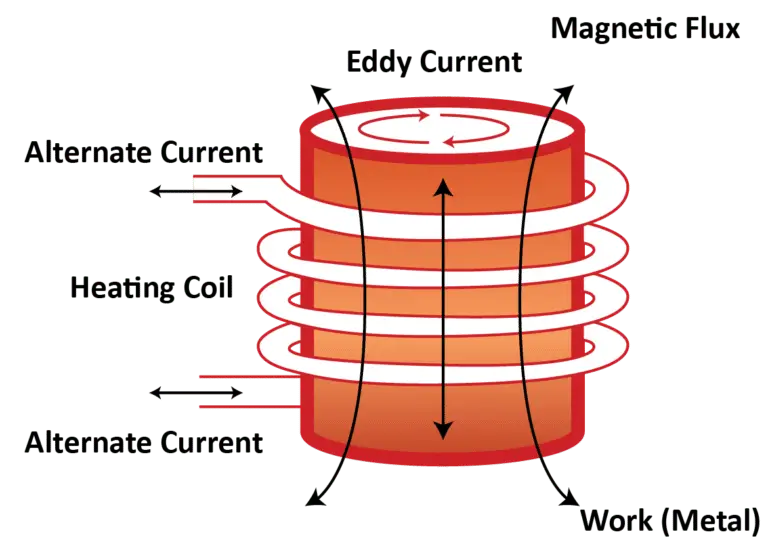

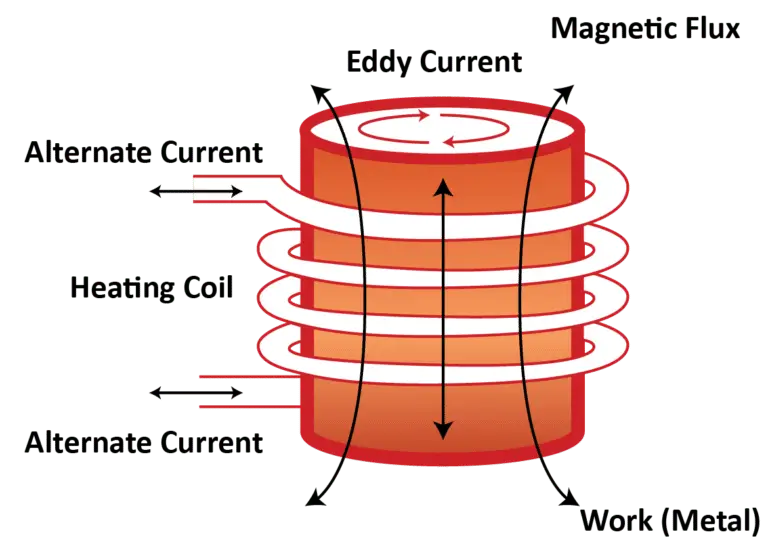

Induction billet and bar heating involve the use of electromagnetic fields to heat metallic materials quickly and uniformly. The process relies on the principle of electromagnetic induction, where alternating current generates an oscillating magnetic field that induces electrical currents within the billets or bars. These induced currents produce heat due to the inherent electrical resistance of the material. Billets or bars are heated before deformation to improve their ductility and strength. Fig.1 demonstrates the working principle of induction heating.

II.Working Principle of Induction Heating Units

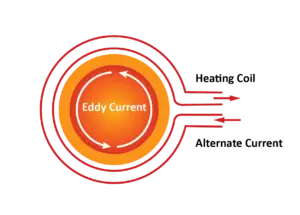

Induction heating units consist of three primary components: a power supply, a work coil, and the work metal being heated (billet or bar). Fig. 2 shows the primary components of an induction heating unit. The power supply generates high frequency alternating current, typically in the radio frequency (RF) range. This alternating current passes through the work coil, creating a rapidly alternating magnetic field.

When the billet or bar is placed within the work coil, the magnetic field induces electrical eddy currents within the material. The resistance of the material causes these currents to dissipate energy in the form of heat, resulting in the desired heating effect.

III. Common Causes of Power Loss

Power loss in induction billet and bar heating can occur due to various factors. Identifying and addressing these causes are crucial for maintaining efficient heating processes. The following are some common reasons for power loss:

- Magnetic Leakage: Improperly designed or poorly maintained work coils can lead to magnetic leakage, where a significant portion of the magnetic field escapes the workpiece. This loss results in reduced heating efficiency.

- Inadequate Coupling: Insufficient coupling between the work coil and the billet or bar can cause poor energy transfer, leading to power loss. This issue may arise from misalignment, incorrect coil size, or material handling variations.

- Eddy Currents in Non-Heating Components: Eddy currents induced in the furnace structure, fixtures, or other non-heating components contribute to unnecessary power dissipation, reducing overall efficiency.

IV. Key Strategies for Preventing Power Loss

To optimize induction billet and bar heating processes and minimize power loss, the following strategies can be implemented:

- Optimize Work Coil Design: Proper design and maintenance of the work coil are critical for efficient heating. Minimizing magnetic leakage by using suitable materials, ensuring tight coil-to-workpiece coupling, and regular inspection and maintenance can significantly reduce power loss.

- Precise Alignment and Positioning: Accurate alignment and positioning of the billet or bar within the work coil improves energy transfer and heating efficiency. This includes considering factors such as coil dimensions, material handling mechanisms, and process control.

- Material Selection and Conditioning: Choosing the appropriate billet or bar material and ensuring its surface cleanliness and conditioning can enhance electrical conductivity and reduce power loss. Surface defects or contaminants can result in localized heating and inefficient power utilization.

- Shielding and Insulation: Shielding non-heating components from the magnetic field and providing proper insulation help minimize eddy currents and power dissipation. Insulating materials such as ceramics or high-temperature polymers can be used to reduce energy losses.

- Accurate Control of Power Supply: Using advanced power control technologies can regulate the energy supply to the induction heating unit, minimizing power wastage.

- Regular Maintenance: The regular upkeep of the induction heating unit, including the coil and power supply, can prevent power loss due to wear and tear or malfunction.

V. Proactive Measures to Mitigate Power Loss in Induction Billet and Bar Heating

Here’s a step-by-step guide on how to efficiently reduce power loss in induction heating:

- Identify Inefficiencies: Conduct an audit to identify the specific areas where power loss is occurring in the induction heating unit. This can be due to outdated equipment, improper usage, or lack of maintenance.

- Upgrade or Replace Equipment: Old or inefficient equipment can contribute to significant power loss. Upgrading to modern induction billet and bar heating equipment can result in substantial energy savings.

- Train Personnel: Regular training of personnel on best practices and optimal operation of induction heating units can prevent misuse and improve efficiency.

- Implement Energy Saving Technologies: Invest in energy-saving technologies such as advanced power control systems, improved coil designs, and efficient cooling systems to minimize power loss.

- Schedule Regular Maintenance: Regular maintenance of the induction heating unit can detect and rectify issues early on, preventing any undue power loss

VI. Conclusion

The industrial heating sector has been experiencing a paradigm shift with the move towards energy-efficient operations. In the arena of induction billet heating and induction bar heating, preventing power loss is of paramount importance. By understanding the underlying principles of an induction heating unit, employing smart strategies, making informed decisions, optimizing work coil design, ensuring precise alignment and positioning, selecting suitable materials, and implementing shielding and insulation measures, power loss can be significantly reduced. By following these strategies, industries can enhance productivity, improve energy efficiency, and achieve cost-effective heating operations.

Remember, every watt saved in induction billet and bar heating is a step towards a sustainable and economically viable industrial landscape. A conscientious approach to preventing power loss in your induction heating processes is not just beneficial – it’s necessary.

References:

Walther, A. “Induction Billet Heaters With Enthalpy Controlled Zone Heating.” In International Scientific Colloquium, Modelling for Electromagnetic Processing, Hannover, pp. 235-241. 2008.

Ahn, Chi-Hyung, Jinbok Lee, Dong-Jin Kim, and Hyun-Oh Shin. “Development of a novel concrete curing method using induction heating system.” Applied Sciences 11, no. 1 (2020): 236.

Semiatin, S. L. Elements of induction heating: design, control, and applications. Asm International, 1988.