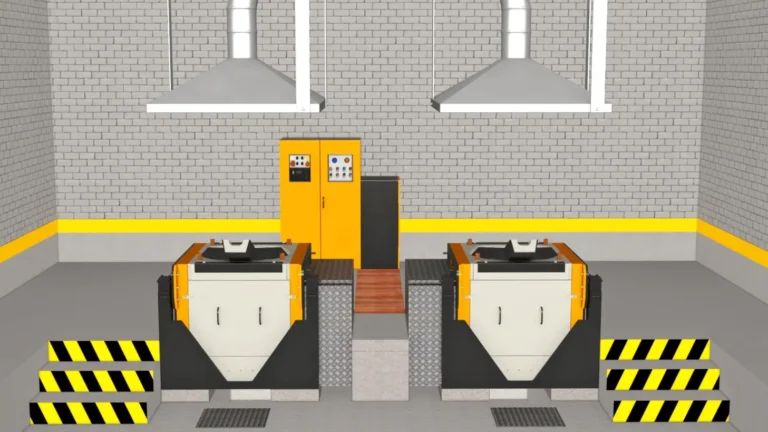

A Modern Induction Smelter for Smelt Ore (Metal Precipitate/Concentrate)

What is induction smelting?

Induction smelting is a process that uses an electric current to heat and melt metal without any direct contact between the metal and the heating source.

The electric current is generated by an induction coil that surrounds a refractory crucible containing the metal charge which is metal concentrate or precipitate. The coil is connected to a power supply that converts AC power into DC power and then into high-frequency AC power.

The high-frequency AC power creates a rapidly changing magnetic field around the coil, which induces eddy currents in the metal charge. These eddy currents generate heat by Joule effect, which melts the metal in minutes.

Modern Induction smelter components

A modern induction smelter takes advantage of an electromagnetic property that spite of have been discovered back in 1831 in Michael Faraday’s laboratory, has been developed and perfected through scientific knowledge to the point where became state-of-the-art technology. This technology currently uses:

Many-core microprocessors housed in a Programmable Logic Controller (PLC) to process data and process variables instantly. This allows for automatic, uniform, and strict process control with no batch-to-batch variations, errors, or delays.

A user-friendly, intuitive, full-color Human Machine Interface (HMI) that uses the keyboard and data stored in the PLC’s large memory to display the operation history, create graphs, and generate reports. This information can be used to make informed decisions about your business using the best statistics.

Insulated gate bipolar transistors (IGBTs) that are switched at high frequency to create an electromagnetic field that induces high currents (eddy currents) in the metallic charge deposited in the refractory crucible. This causes fusion in just minutes.

Resonant coils and capacitors, a technology that has been used, among others, in radio and television since their inception to tune broadcasts. Here, it is used at high amperage to achieve maximum efficiency in melting a metallic mass without fumes, energy waste, or contamination.

A nice feature of this equipment is that spite of being an inductive circuit because, basically, it is a transformer with no iron core and whose secondary is the own metallic load into the refractory crucible, its power factor * is greater than 0.96 under any load condition.

How does an induction smelter work?

An alternating current applied to a coil will produce a rippling magnetic field in the environment of the coil. If we place a metal block into the variable magnetic field, there will be eddy currents circulating through the metal block, which constitutes a closed circuit.

Those eddy currents vary with the frequency of the current flowing through the coil, replicating the frequency value in the metallic block.

The Joule effect, causes the metal to be heated. The larger the value of the eddy current, the greater the heat generated and the hotter the metal mass.

So if we suppose negligible losses on the coil, the energy of the current through the coil has been completely converted into heat energy on the metal block.

We have said above that an induction smelter is a transformer with no iron core and whose secondary is the own metallic load into the refractory crucible.

When an alternating current whose frequency is f, flows through a copper primary winding whose number of turns is n1, will generate variable magnetic flux ɸ through the metal (secondary coil, whose number of turns is n2=1) to generate the following electromotive force E2:

E2 = 4.44 ɸ f n2 10-8 (V)

And the electric current I2 (eddy currents) generates a great deal of heat to melt the metal.

So, the I2 current and heat energy W present in the metal load are:

Resistivity ρ is measured in Ω.m, and depends on the material melted in the smelter crucible. Some resistivity values are:

Why should you choose a modern induction smelter for smelting ore?

If you are looking for a way to smelt ore like a pro, you should choose a modern induction smelter for many reasons:

A modern induction smelter can melt metal faster, better, safer, and cheaper than conventional methods.

A modern induction smelter can produce high-quality metal with no contamination or oxidation, which improves its performance and value.

A modern induction smelter can reduce your energy consumption and emissions by up to 70%, which saves you money and protects the environment.

A modern induction smelter can offer you more control and flexibility over your melting process, thanks to its advanced features and functions.

A modern induction smelter can provide you with valuable information and insights on your melting process, thanks to its data storage and analysis capabilities.

So don’t hesitate. Upgrade your metal casting business with a modern induction smelter today and enjoy the benefits of state-of-the-art technology.

If you want to learn more about induction smelting and how to choose the best modern induction smelter for your needs, contact us today. We are experts in electric metal smelting and we can help you find the perfect solution for your business.

References:

https://www.rubamindrc.com/copper_smelting.php

https://www.electricaldeck.com/2022/05/induction-heating.html

https://byjus.com/physics/resistivity-various-materials

https://toshiba.semicon-storage.com/us/semiconductor/knowledge/faq/mosfet_igbt/igbt-014.html