How to Melt Copper Using Induction Furnaces?

Introduction

Copper is one of the most valuable industrial metals thanks to its excellent conductivity and versatility. It is widely used in electrical wiring, piping, electronics, construction, and countless manufacturing applications. To meet global demand, industries need reliable and efficient ways to melt copper, whether from raw cathodes or recycled scrap. As a premier provider, Electroheat Induction utilizes advanced IGBT technology to deliver furnaces that efficiently melt copper through electromagnetic induction. This method ensures purity and uniform, contactless heating, thereby eliminating contamination often associated with flame-based systems.

Melting Copper with Induction Furnaces

Copper melts at 1,981 °F. An induction furnace precisely maintains this temperature for consistent, uniform melting.

The process involves:

- Charging: Copper scrap or cathodes go into the crucible.

- Heating: Electromagnetic induction quickly raises the metal’s temperature.

- Melting: Copper liquefies uniformly under precise control.

- Dross Skimming: Surface impurities are removed.

- Pouring: Liquid copper is cast into molds.

Specifications:

- Output Power Rating: 50 kW to 5000 kW

- Melting Capacity: 50 kg to 5 tons working capacity

- Application: Suitable for medium and large-sized applications

- Frequency: Medium and Low frequency depends on the application

Induction heating works by converting electrical energy into a magnetic field that penetrates the copper. This field creates internal eddy currents, heating the metal uniformly from within, without direct contact. Unlike gas or oil-fired furnaces, induction furnaces maintain consistent heat, leading to purer final products with better mechanical strength.

The Copper Melting Induction Furnace Process

In an induction melting furnace for copper scrap, an electric coil generates a magnetic field. This field induces currents directly inside the copper, heating it from within. This method delivers:

- Uniform heating with less oxidation.

- Precise control of temperature at every stage.

- Flexibility for melting pure copper or alloys.

- Lower dross formation, ensuring higher purity and yield.

This controlled copper melting induction furnace process allows industries to achieve consistent quality and efficient operations. This process not only saves energy but also minimizes oxidation and material loss — crucial for industries producing high-purity copper alloys.

Benefits of Induction Copper Melting

- Energy Efficiency

Induction furnaces operate at 60–75% efficiency, much higher than many fuel-fired systems. Energy is applied directly to the metal rather than wasted in heating surrounding materials. - Non-Energy Benefits (NEBs)

Beyond energy savings, induction furnaces provide numerous NEBs:

- Improved product quality – higher purity, stronger copper, less oxidation.

- Environmental gains – no combustion gases or smoke, reduced CO₂ emissions.

- Reduced maintenance – fewer moving parts, no burners or chimneys.

- Safety – no open flames, lower risk of accidents.

- Productivity – faster melt cycles, stable operation, less downtime.

- Repeatable process – temperature and heating patterns remain consistent across multiple melts, ensuring predictable quality every time.

3. Cost Savings

Lower energy bills, fewer maintenance needs, and higher yield from scrap translate into substantial long-term savings.

Induction Melting of Copper Scrap

Induction furnaces are essential for transforming various forms of copper scrap, from wires and rods to pipes and industrial returns, into valuable resources. By harnessing these advanced systems, industries can dramatically reduce raw material costs while actively championing critical sustainability initiatives. An induction melter for copper scrap meticulously ensures the efficient recovery of invaluable material, consistently delivering minimal impurities, making it perfectly prepared for seamless integration into the production of high-quality new products.

Induction vs. Fuel-Based Copper Melting

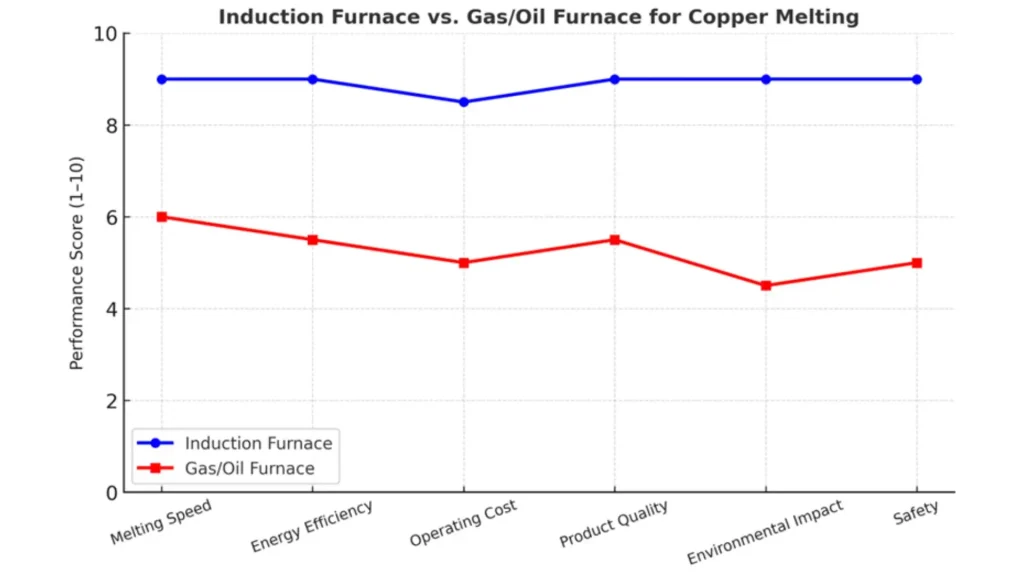

When compared with traditional gas or oil-fired furnaces, induction furnaces deliver clear advantages. Table 1 below compares induction and fuel-based furnaces, showing clear differences in performance, cost, and environmental impact.

| Feature | Induction Furnace | Gas/Oil Furnace |

| Melting Speed | Fast, even heating | Slower, uneven |

| Energy Efficiency | High – minimal energy loss | Lower – fuel wasted |

| Operating Cost | Lower (electricity-based) | Higher (fuel + maintenance) |

| Product Quality (NEB) | Cleaner melt, fewer impurities | More oxidation, lower purity |

| Environmental Impact | No combustion gases, lower CO₂ | Pollutants and smoke |

| Safety (NEB) | Safer – no open flames | Higher risk from fuel handling |

As illustrated above, an induction furnace copper melting system outperforms gas or oil furnaces across all key performance metrics — including efficiency, safety, and product quality.

Performance Snapshot

In addition to the table, the chart below highlights how induction technology consistently outperforms traditional methods in efficiency, safety, and quality.

Why Choose Electroheat Induction

Electroheat Induction stands out as a global leader in crafting induction furnaces for copper melting and recycling, boasting over a decade of specialized expertise. Our focus is squarely on innovation and ensuring our customers are delighted, guaranteeing dependable performance with every setup. Here’s what we bring to the table:

- Global installation and technical support to keep you running smoothly.

- Cutting-edge IGBT technology for operations that are both efficient and super reliable.

- Expert guidance and consultations to help you fine-tune your processes and save energy.

- Tailored furnaces designed specifically for foundries, recycling plants, and alloy manufacturers.

👉 Reach out to us today to discover more about our copper melting induction furnaces and how they can truly revolutionize your production process!