Introduction

Modern industries—from metal casting to power generation—rely heavily on cooling systems to prevent equipment overheating and ensure stable operation. However, in regions facing water scarcity or environmental constraints, traditional wet cooling systems can pose serious limitations. This is where the dry type cooling tower comes in.

A dry cooling tower offers a reliable, low-maintenance solution that eliminates water consumption while delivering consistent performance. In this article, we explore how dry cooling towers work, their construction, configurations, benefits, and why they are the future of industrial and commercial cooling.

What Is a Dry Type Cooling Tower?

A cooling tower is a heat removal device used to discharge excess heat from processes or machinery into the atmosphere. While wet cooling towers rely on evaporative cooling, dry cooling towers use only air for heat dissipation, making them ideal for environments where water conservation is a priority.

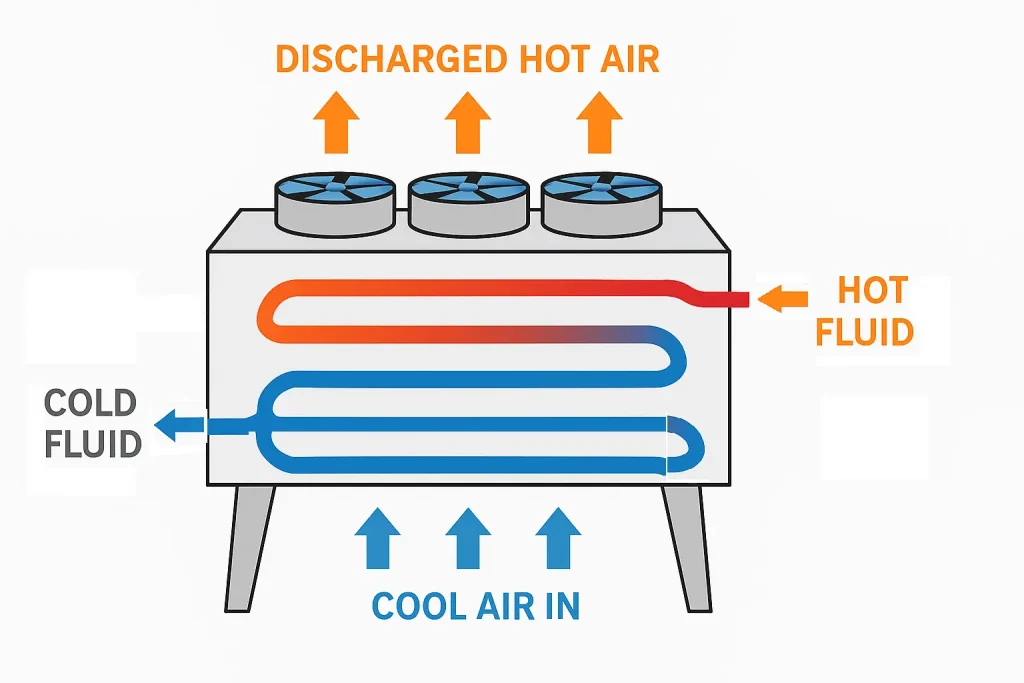

In a dry cooling tower, hot process fluid circulates through finned coils or heat exchangers. Ambient air is blown or drawn over these coils, absorbing the heat and releasing it into the atmosphere. The fluid, now cooled, is recirculated back into the process.

This system is fully enclosed, meaning no water evaporates, and the process fluid never contacts the air directly—characteristics that define a closed circuit cooling tower.

How a Dry Cooling Tower System Works

A dry cooling tower system transfers heat from industrial processes to the surrounding air without water loss. There are two main types of dry cooling systems:

3.1 Direct Dry Cooling

– The hot process fluid flows directly through finned tubes or coils.

– Air passes over the coils, removing heat by convection.

– The cooled fluid returns to the process line.

3.2 Indirect Dry Cooling

– Heat is first transferred from the process fluid to an intermediate fluid in a heat exchanger.

– This secondary fluid circulates through the dry cooling tower coils.

– Air removes heat from the secondary loop.

In both systems, fans are used to move air over the heat exchange surfaces. Sensors, valves, and controllers regulate flow and temperature, ensuring optimal operation.

Dry Cooling Tower Construction and Components

A typical dry cooling tower includes:

- Finned tube heat exchangers – where heat transfer occurs

- Fans – to draw or force ambient air through the heat exchangers

- Piping network – for the closed-loop circulation of the coolant (water or glycol)

- Casing/Housing – enclosing and supporting system components

This simple yet robust structure makes dry towers cost-effective, modular, and adaptable to a wide range of environments.

Types of Dry Type Cooling Towers

Dry cooling towers can be classified based on airflow direction and fan positioning. The two most common types are:

5.1 Forced Draft Dry Cooling Tower

- Fans are located at the base and push air over the heat exchange coils.

- The entire structure is enclosed to direct airflow efficiently.

- Often used in small to mid-sized industrial cooling tower applications.

5.2 Induced Draft Dry Cooling Tower

- Fans are mounted at the top to pull air through the system.

- Offers better airflow control and heat rejection.

- Suitable for larger installations with higher heat loads.

5.3 Natural Draft Dry Cooling Tower (NDACC)

- Operates without fans by utilizing the buoyancy of hot air to create natural convection

- Reduces energy consumption

- Typically used in large power stations or environmentally sensitive projects

All types can be customized by a cooling tower manufacturer to meet specific industry or environmental needs.

Advantages of a Dry Cooling Tower System

Opting for a dry cooling tower provides numerous operational and environmental benefits:

- Water Conservation: Uses air instead of water, reducing operating costs and dependency on water sources.

- Low Maintenance: No water treatment required; fewer scaling and corrosion issues.

- Environmental Compliance: Zero water discharge, ideal for locations with strict environmental regulations.

- Energy Efficiency: Designed with optimized airflow and finned surfaces for effective heat rejection.

- Longevity: With fewer moving parts and corrosion-resistant materials, dry towers have long operational lifespans.

Applications of Industrial Dry Cooling Towers

Industrial cooling towers are critical in various sectors. Dry cooling towers, in particular, are widely used in:

- Foundries and metal processing plants

- Power generation and substations

- Oil and gas facilities

- Data centers and server rooms

- HVAC systems in commercial buildings

- Hospitals, pharmaceutical, and chemical plants

Their water-saving capabilities make them especially suitable for arid regions, green-certified buildings, and facilities seeking to reduce water and energy footprints.

Dry Cooling Tower vs. Wet Cooling Tower: What’s the Difference?

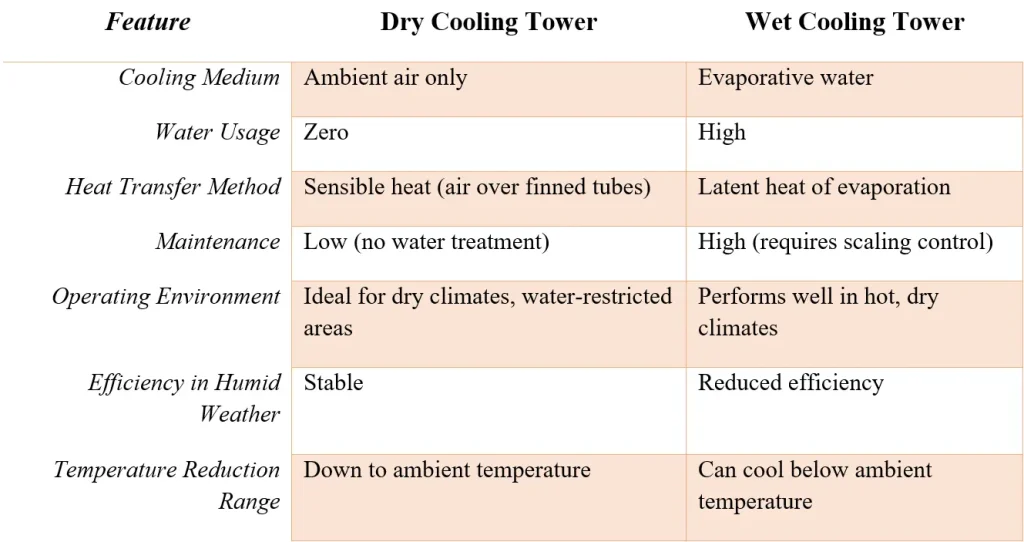

In industrial and commercial cooling applications, decision-makers often compare dry cooling towers and wet cooling towers to determine the best fit for operational needs. While both systems serve the same purpose—removing process heat—they differ significantly in their cooling medium, efficiency, environmental impact, and maintenance demands.

Conclusion

As industries move toward sustainable and cost-effective solutions, dry cooling towers have emerged as a preferred option for many facilities. Their ability to deliver consistent cooling performance without consuming water gives them a significant edge over conventional systems.

If you’re looking for a reliable cooling tower manufacturer that specializes in advanced, customized dry cooling systems, Electroheat Induction is here to support your industrial cooling needs.

Our Videos

Watch our Videos