Introduction to Induction Furnaces for Silver Melting

When it comes to melting and processing silver, precision and efficiency are key. In the world of metallurgy, the use of induction furnaces has revolutionized the way we melt and smelt various metals, and silver is no exception.

In this comprehensive guide, we will delve into the intricacies of utilizing an induction furnace for silver melting. We will explore the advantages it offers, techniques for melting silver with these furnaces, and the critical pouring stage where induction melting for silver plays a crucial role.

Silver Melting with Induction Furnaces: A Paradigm Shift

1.The Working Principle of Induction Furnaces

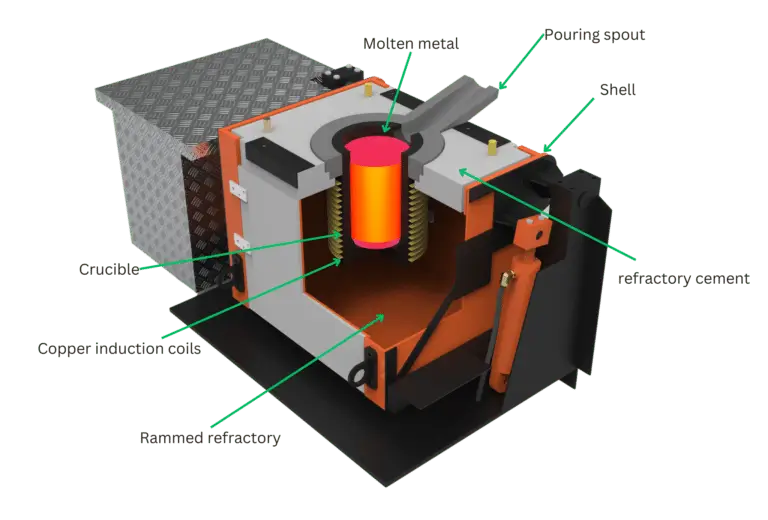

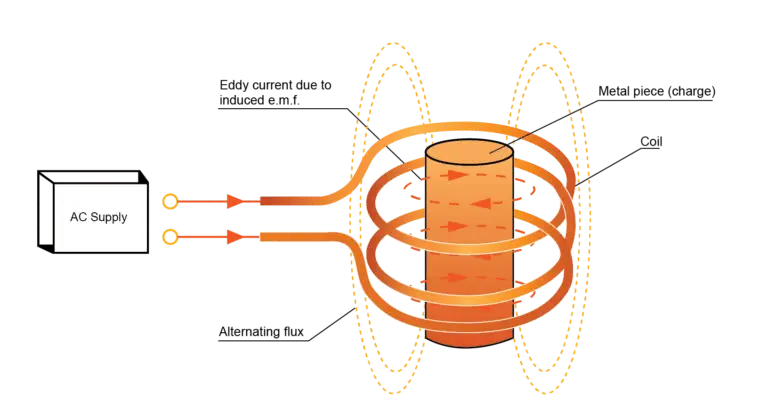

Induction furnaces utilize electromagnetic induction to generate heat within the metal itself, resulting in a highly precise and controlled melting process. Induction furnaces for melting silver operate on the principle of electromagnetic induction. An alternating current (AC) is passed through a coil, creating a powerful electromagnetic field. When a silver crucible or container is placed within this field, it rapidly heats the metal through induction. The working principle of an induction furnace is shown in Figure 1. Induction furnaces can be specifically designed for melting silver, providing a range of benefits that make them the preferred choice for professionals in the field.

Advantages of Using Induction Furnaces for Silver Melting

1. Precision and Control:

One of the primary advantages of employing an induction furnace for smelting silver is the exceptional precision and control it offers. These furnaces use electromagnetic induction to generate heat directly within the material to be melted. This results in even and consistent heating, minimizing the risk of overheating or underheating the silver. The precise temperature control ensures that the silver is melted without any loss of quality. The basic diagram of a temperature control system for heating furnace is shown in Figure 3.

2. Energy Efficiency: Induction furnaces are highly energy-efficient. They operate with minimal heat loss, making them a sustainable and cost-effective choice for melting silver. This efficiency not only saves energy but also reduces operational costs.

3. Clean and Safe: Unlike traditional methods such as open-flame torches or furnaces, induction furnaces do not produce harmful emissions or fumes. This clean and safe operation is essential, especially when working with precious metals like silver. The absence of noxious gases makes it a healthy and environmentally responsible choice.

4. Reduced Dross Formation: Dross is an undesirable byproduct that can occur during the melting process. With induction furnaces, the risk of dross formation is significantly reduced, leading to higher yields and less material wastage.

5. Quick Melting: Induction furnaces are known for their rapid heating capabilities. They can quickly bring silver to its melting point, saving time and improving overall efficiency.

Techniques for Melting Silver with Induction Furnaces

Melting silver with an induction furnace is a well-defined process that requires careful preparation. Here are the key steps to ensure a successful silver melting operation:

1.Preparation: Before melting silver, ensure that the silver pieces are clean and free from contaminants. Proper preparation is crucial when using an induction furnace for melting silver. Clean and dry silver ensures a smooth and efficient melting process.

2.Loading: Place the prepared silver pieces into the crucible of the induction furnace. The amount of silver should be carefully measured to avoid overloading the crucible.

3.Setting Parameters: The furnace operator should set the desired temperature and heating duration based on the type and quantity of silver being melted. This is where the precise control of an induction furnace comes into play.

4.Heating: Start the melting process by activating the furnace. The electromagnetic induction generates heat within the crucible, gradually melting the silver. Ensure a controlled and gradual increase in temperature to prevent overheating.

5.Monitoring: During the melting process, it’s essential to monitor the silver’s temperature to prevent any adverse reactions or overheating. The operator can adjust the settings as needed.

6.Skimming: If any dross or impurities rise to the surface, carefully skim them off to maintain the quality of the molten silver.

7.Pouring: The final step in the silver melting process involves transferring the molten silver to the desired molds or containers. As depicted in Figure 4, the pouring process is a critical step in silver melting, with molten silver flowing from the crucible. This is where induction melting for silver truly shines. The precise control and even heating offered by induction furnaces ensure that the molten silver can be poured accurately and without spillage. Whether you are creating silver bars, jewelry components, or other silver products, the pouring stage is critical to achieving the desired results.

Conclusion

The utilization of an induction furnace for silver melting has transformed the way we work with this precious metal. The precision, efficiency, and control it offers make it the top choice for professionals in the field. By following the proper techniques and taking advantage of the benefits of induction furnaces, the silver melting process becomes not only more efficient but also more environmentally friendly. So, whether you are in the jewelry industry, metal casting, or any other field that requires silver melting, consider adopting induction furnaces for a cleaner, safer, and more precise approach.

References

Lavrov, Sergey. “Smelting induction furnace for metal, diagram, properties of types. Homemade induction furnace for melting metal Homemade induction furnace for melting metals.”

Dejaeghere, Laurent, Thomas Pierre, Muriel Carin, PHILIPPE LE MASSON, and Mickael Courtois. “Design and development of an induction furnace to characterize molten metals at high temperatures.” High Temperatures–High Pressures 47, no. 1 (2018).

Abashkin, A. Yu, I. N. Skrigan, E. Yu Ivanov, A. O. Pleshakov, D. B. Lopukh, A. V. Vavilov, and A. P. Martynov. “Investigation of silver behavior in the glass melt and its effect on the IMCC conditions in an industrial-scale furnace during vitrification of HLLW simulants.” MRS Advances 5, no. 1-2 (2020): 83-92.

Ristiana, Rina, Arief Syaichu-Rohman, and Pranoto H. Rusmin. “Modeling and control of temperature dynamics in induction furnace system.” In 2015 5th IEEE international conference on system engineering and technology (ICSET), pp. 6-11. IEEE, 2015.

Our Videos

Watch our Videos