1. Introduction

In the high-stakes world of metal process operations, furnace performance can define the success—or failure—of an entire production line. As global demand for metal processing grows more competitive, businesses are realizing that efficiency, precision, and sustainability are no longer optional—they’re essential. This is where the role of a foundry and mining furnace consultant becomes pivotal.

Whether you’re running a cast iron foundry, a copper smelter, or an aluminum refinery, expert furnace advisory ensures your thermal systems deliver consistent performance while minimizing energy losses, emissions, and operational risks. With the right consultant, you’re not just investing in equipment—you’re investing in transformation.

2. Role of a Induction Furnace Consultant

A consultant serves as a bridge between engineering theory and operational reality. Their role extends beyond basic troubleshooting—they offer comprehensive strategic support across the lifecycle of your thermal systems.

Core Services Include:

- Furnace system diagnostics and efficiency audits

- Heat distribution modeling and thermal mapping

- Layout planning for optimal material flow

- Melt quality enhancement and yield improvement

- Lifecycle cost analysis and upgrade planning

Who Benefits?

- Iron and steel foundries

- Non-ferrous smelters (copper, zinc, aluminum)

- Mining operations with integrated thermal processing

- OEMs and EPC contractors seeking furnace design expertise

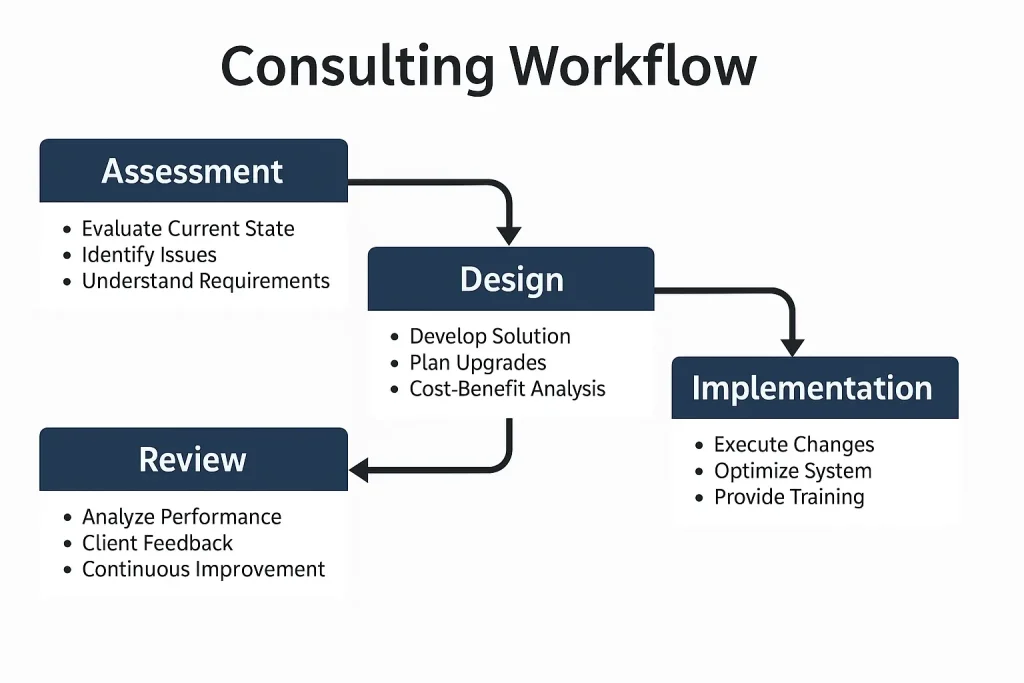

The consulting process is structured to deliver actionable insights and customized furnace optimization. Below is a typical workflow that illustrates how an expert consultant guides foundry and mining clients from initial assessment to implementation and ongoing support.

3. Specialized Consulting Areas

3.1 Induction Furnace Design Consultant

Designing a furnace system is not just about heat — it’s about geometry, metallurgy, flow dynamics, and controls.

Key deliverables:

- Custom furnace architecture (coreless, channel, crucible, etc.)

- CFD simulations for air, slag, and metal flow

- Space-optimized layout for vertical or horizontal installations

- Recommendations for refractory lining and insulation

- Integration of cooling towers and fume extraction systems

3.2 Melting Furnace Expert

A smelting furnace expert focuses on the heart of production—where ore becomes value.

Expertise includes:

- Tuning smelting parameters for optimal recovery

- Minimizing slag formation and metal losses

- Advising on additives and flux usage

- Adapting smelting cycles to variable feedstock quality

- Improving furnace tapping, pouring, and casting steps

3.3 Metal Process Engineering

Furnaces don’t operate in isolation. Process engineering ensures thermal systems are seamlessly embedded into upstream and downstream operations.

Typical services:

- Material handling optimization

- Preheat zone design and energy recovery

- Integration with rolling mills, molding lines, or pelletizers

- Smart automation and data logging frameworks

- Process simulation and KPIs analysis

3.4 Metal Processing Equipment Consulting

Poor equipment pairing can undermine even the best furnace design.

Consultants help:

- Evaluate and size induction coils, transformers, crucibles, and cooling towers

- Choose between IGBT or SCR power systems

- Recommend modular vs. monolithic construction

- Retrofit outdated systems to improve efficiency

- Ensure spare parts availability and mechanical reliability

3.5 Industrial Furnace Consultant

Industrial clients benefit from wide-scope advisory that considers safety, compliance, and digitalization.

Offerings include:

- – HMI/SCADA integration and control panel upgrades

- – Safety interlocks and emergency cut-offs

- – ISO, OSHA, and local code compliance

- – High-frequency vs. medium-frequency selection

- – Digital twin modeling for predictive maintenance

4. Why Expert Advisory Matters

Hiring a furnace consultant isn’t just about fixing what’s broken—it’s about unlocking untapped potential in your system. The right advisory team can:

- – Cut energy costs by 10–30% through improved thermal cycles

- – Extend furnace life with proper material and design choices

- – Reduce downtimes with preventive maintenance schedules

- – Boost output quality by controlling alloy composition and temperature uniformity

- – Meet sustainability goals by lowering emissions and material waste

5. Choosing the Right Melting Furnace Design Consultant

When selecting a consultant, consider:

- – Experience Across Furnace Types: Induction and other furnace

- – Hands-On Industrial Exposure: Not just theoretical modeling

- – Vendor-Neutrality: Recommending the best tech, not just brand partners

- – Data-Driven Reporting: Thermal imaging, melt analysis, ROI modeling

- – Commitment to Continuous Support: Installation to commissioning and beyond

6. Why Electroheat Induction Is Your Ideal Partner

Electroheat Induction doesn’t just manufacture world-class induction systems—we engineer performance. As a industrial furnace consultant, we offer:

- –Proven field experience in over 20+ countries

- – In-house R&D, design, and simulation tools

- – Customized furnace solutions for diverse smelting needs

- – Full lifecycle support—from design to spare parts and training

- – Trusted advisory in mining, automotive, aerospace, and metal casting sectors

With Electroheat, you don’t just buy equipment—you gain a strategic partner in thermal excellence.

8. Conclusion

Thermal systems are capital-intensive and mission-critical. Getting them right requires more than equipment—it requires insight. By engaging a skilled foundry and mining furnace consultant, your operation gains the tools, design clarity, and efficiency edge to outpace competitors.

Whether you’re scaling up production or modernizing an aging furnace line, partner with Electroheat Induction—where technology meets expertise.