1. Introduction

Modern metal processing demands technology that’s efficient, precise, and sustainable. Electroheat Induction delivers exactly that — advanced induction melting furnaces built for speed, energy savings, and consistent performance.

Powered by cutting-edge IGBT technology, our systems ensure faster, uniform melting with lower environmental impact, making them the trusted choice for foundries, refineries, and industrial plants worldwide.

2. What Is an Induction Melting Furnace?

An induction melting furnace operates by utilizing electromagnetic induction to generate thermal energy directly within a conductive metal charge, facilitating the melting of diverse materials including steel, iron, copper, aluminum, brass, bronze, silicon, gold, and silver. This non-contact heating methodology offers several distinct advantages:

- Clean operation, free from combustion gases or fuel contamination.

- Uniform melting and precise temperature control.

- Reduced dust and emissions compared to traditional methods.

Typical operational ranges include:

- Output Power: 50 kW – 10,000 kW

- Melting Capacity: 50 kg – 15 tons

3. Key Features and Technological Advantages

Electroheat’s industrial induction melting furnaces are engineered for maximum efficiency and productivity. The table below outlines their core features and the distinct advantages each provides:

| Feature | Advantage |

| Advanced IGBT Power Controls | Improved melting rates and reduced electrical losses. |

| Optimized Coil Winding | Higher energy transfer and uniform heating. |

| Smart Power Circuitry | Maintains stable load and prevents over-demand. |

| Dual Cooling Turns | Even temperature distribution and longer coil life. |

| Magnetic Shunts | Lower stray losses and overheating prevention. |

| Compact Design | Space-saving layout ideal for modern facilities. |

| Hydraulic Tilting System | Smooth, safe pouring of molten metal. |

| Low Maintenance Build | Extended crucible life and minimal downtime. |

Further advancements in power electronics, such as those incorporating Field-Programmable Gate Arrays, enable even more adaptable control systems to optimize performance based on real-time operational conditions, like varying pot types, as demonstrated in recent induction heater developments.

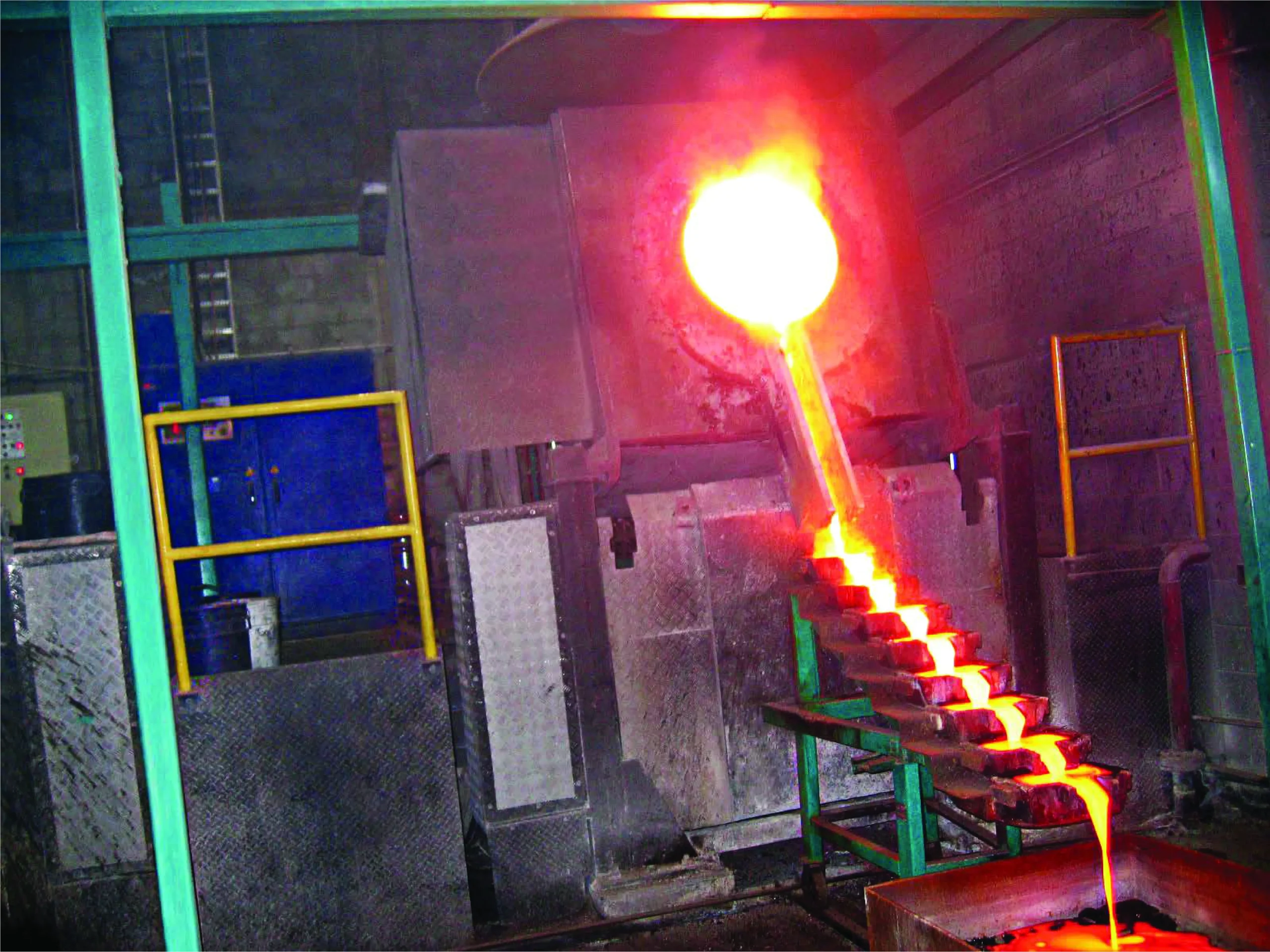

The setup illustrated below shows the main system components and power configuration used in modern Electroheat induction melting furnace installations.

Figure 1. Typical Induction Melting Furnace Setup. (by Electroheat.

(a) Induction Power Supply and Control Cabinet – the smart IGBT-based power and control unit that delivers stable electrical energy to the furnace coil with real-time monitoring.

(b) Dual-Crucible Coreless Furnace Assembly – tilting furnace units for melting and pouring operations, designed for high efficiency and continuous production.

4. Efficiency and Performance Benefits

Electroheat’s industrial induction melting furnaces revolutionize metal processing, combining pinpoint heating with advanced control to dramatically improve energy efficiency and metallurgical quality. A 2024 Research Square study demonstrated how FPGA-based digital controllers enhance the responsiveness and accuracy of induction heating systems used in industrial furnaces.

Discover the powerful benefits that set Electroheat’ Induction furnaces apart:

- Exceptional Efficiency: Achieve a remarkable 70–85% electrical-to-thermal conversion, meaning more of your energy goes directly into melting, not waste.

- Flawless Uniformity: Say goodbye to inconsistencies. Our furnaces guarantee perfectly uniform melts, free from hot spots or contaminating fuel residues.

- Dramatic Cost Savings: Experience lower operating expenses thanks to reduced energy waste during idle times and lightning-fast melt cycles.

- A Greener Footprint: Operate with peace of mind. Our eco-friendly technology produces zero CO₂ or harmful particulate emissions.

- Superior Metal Quality: Our integrated medium-frequency induction systems create a natural stirring action, ensuring your alloys are perfectly blended, homogeneous, and consistently high-quality, batch after batch.

5. Industries We Serve

Electroheat furnaces are the trusted choice across a vast spectrum of industries, powering critical operations from large-scale production to precision research:

- Foundries & Heavy Industry: Powering casting operations and major steel and aluminum plants.

- Precious Metals & Electronics: Essential for refineries, recycling, silicon, and semiconductor production.

- Advanced Manufacturing: Crucial for mining, aerospace, defense, automotive, solar, and general industrial sectors.

- Research & Academia: Facilitating innovation in universities, laboratories, and R&D centers worldwide.

Each installation is meticulously tailored to production goals—whether melting ferrous, non-ferrous, or noble metals—ensuring optimal performance and efficiency.

6. Applications of Induction Melting Furnaces

Our induction furnaces for melting metals are ideal for:

- Copper and Aluminum melting for casting or alloy production.

- Cast Iron and Steel melting for foundry and fabrication use.

- Gold and Silver smelting in mining and refining operations.

- Precision melting for critical laboratory and research applications.

Our advanced digital controls and robust power supplies work together to deliver consistent, reliable results, even in the most demanding industrial environments.

7. Why Electroheat Induction is The Best

As a global leader in induction furnace manufacturing, Electroheat consistently delivers innovation, reliability, and sustainability.

- Global Support: Benefit from worldwide installation and technical support, ensuring uninterrupted operation.

- Custom Solutions: Our expert advisory services tailor each furnace to your precise process and capacity requirements.

- Proven Excellence: Rely on our extensive track record across the mining, foundry, and refining industries.

Our furnaces provide unparalleled performance and cost savings, supported by decades of engineering excellence and a steadfast commitment to environmental responsibility.

👉 Elevate Your Production! Contact us today for a complimentary assessment and a custom quote on a high-efficiency induction melting furnace, perfectly engineered for your needs.

References & Acknowledgments

- U.S. Department of Energy. Industrial Energy Efficiency: Induction Heating Overview. Available at: https://www.energy.gov/

- AZoM – Materials and Engineering. Induction Heating and Melting Principles. https://www.azom.com/article.aspx?ArticleID=11659

- Jalilova, Dinora, et al. “Energy Efficiency of Energy-Intensive Productions and Technologies.” E3S Web of Conferences, vol. 461, Jan. 2023, p. 1095. https://doi.org/10.1051/e3sconf/202346101095

- Villamizar, Jairo, et al. “Building a Fully Digital Controller with Altera Cyclone FPGA and Nios Processor for Induction Heating Application.” Research Square, Oct. 2024. https://doi.org/10.21203/rs.3.rs-5074108/v1

Our Videos

Watch our Videos