1. Introduction

Steel is one of the world’s most essential materials for construction and manufacturing, with demand continuously rising. To meet growing demand, producers are turning to smarter, cleaner, and more efficient melting solutions. Induction furnaces deliver precisely that—fast melting, lower energy costs, and unmatched reliability.

At Electroheat Induction, we specialize in advanced IGBT-powered systems designed for medium and large-scale steel operations, offering global installation, expert support, and proven performance.

Specifications:

- Output Power Rating: 50 kW to 10000 kW

- Melting Capacity: 50 kg to 10 tons working capacity

- Application: Suitable for medium and large-sized applications

- Frequency: Medium and Low frequency depends on the application

2. Why Steel Industries Prefer Induction Furnaces

Most steel plants choose steel induction melting furnaces because they are fast, clean, and versatile. Unlike traditional methods, induction furnaces efficiently melt all grades of steel—including carbon, stainless, and alloy steels—without complications. They not only reduce costs but also ensure a consistent and high-quality melting process.

- High Production Rate

With an induction melting furnace for steel scrap, companies can melt large amounts of steel quickly. The process ensures that steel melts evenly across the furnace, regardless of its size. This even melting allows factories to increase production capacity without needing additional furnaces or equipment. More output with the same setup translates to higher profits. - Controlled Melting Process

One of the biggest advantages of using a steel melting induction furnace is control. Operators can set and adjust the temperature precisely, which is crucial when handling different types of steel. For example, some alloys require lower melting points, while others need higher ones. With induction, the process can be adjusted instantly, ensuring that every batch meets the required standards.

- Lower Operating Costs

Cost efficiency is another major benefit. Traditional furnaces consume a lot of fuel and energy to reach the high temperatures needed to melt steel. An induction furnace for melting steel scrap metal, on the other hand, utilize concentrated electromagnetic heating powered by electricity. This means less wasted energy and reduced operating costs over time. The savings on fuel and maintenance can be significant, making induction furnaces a smart investment for steel producers. - Advanced IGBT Technology

At Electroheat, we design furnaces with the latest IGBT-based induction technology. This advanced system makes our induction furnaces more reliable, energy-efficient, and user-friendly. Features such as automatic load management, power factor above 0.97, and energy monitoring give operators’ peace of mind that the furnace is working at maximum efficiency. As pioneers in this field, we continue to deliver solutions that are both advanced and practical. - Environmental and Safety Benefits

Besides efficiency, induction furnaces are also safer and cleaner. They do not burn fuel or release harmful gases into the atmosphere. This creates a healthier work environment for operators and contributes to sustainability goals. With less heat loss and no direct flames, workers handle steel melting in safer conditions compared to resistance or fuel-fired furnaces.

3. Applications in Steel Plants

Induction furnaces are used widely across the steel industry:

– Melting scrap into new steel products such as billets and ingots.

– Alloying and refining different grades of steel.

– Producing specialty steels for automotive, construction, and manufacturing.

Whether for small foundries or large steel plants, induction furnaces offer unmatched flexibility.

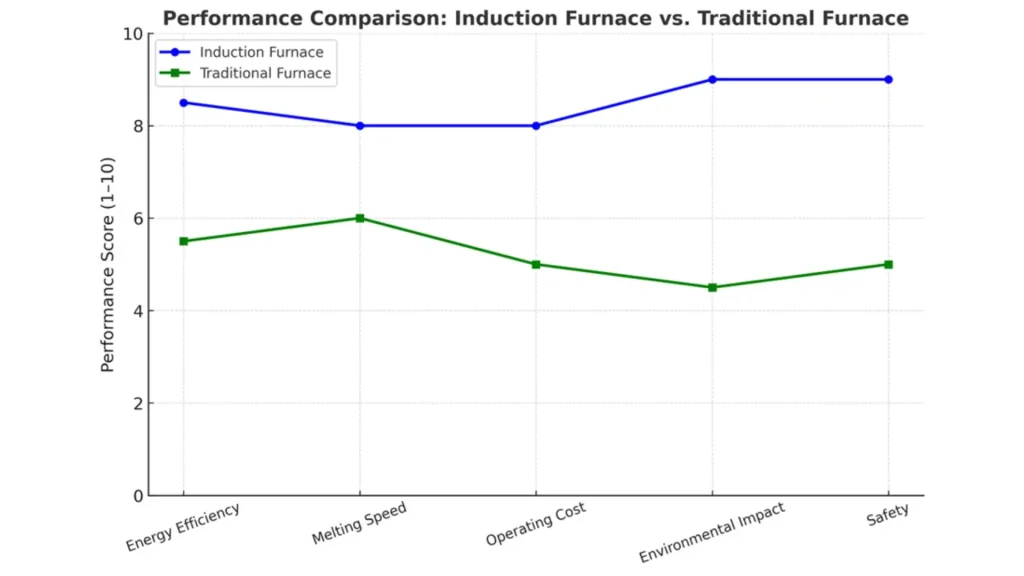

4. Comparison: Induction Furnace vs. Traditional Furnace

The following table presents a verified comparison of induction and traditional furnaces.

| Category | Induction Furnace (Score/10) | Traditional Furnace (Score/10) | Basis / Justification |

| Energy Efficiency | 8.5 | 5.5 | Induction designs show ~10–15 ppt higher efficiency vs. less efficient traditional designs (foundry-planet.com). |

| Melting Speed | 8 | 6 | Induction melts faster with even heating; traditional methods slower due to fuel burn-in and heat lag. |

| Operating Cost | 8 | 5 | Induction saves on fuel and maintenance; electricity more efficient over time. |

| Environmental Impact | 9 | 4.5 | Induction produces fewer emissions and cleaner workspace (no combustion gases). |

| Safety | 9 | 5 | No direct flame handling; safer for operators compared to traditional fuel-fired furnaces. |

Why Choose Electroheat Induction

Electroheat Induction is committed to delivering world-class solutions for steel melting. With worldwide installations, dedicated technical support, and expert consultation services, we stand as a trusted partner for steel manufacturers. Our motto speaks for us: ‘Quality is our Heart – Pioneer in IGBT Technology – Providing Worldwide.’

When it comes to induction furnaces for steel melting, we don’t just supply equipment—we provide reliability, efficiency, and a long-term solution for the future of steel production.

Our Videos

Watch our Videos