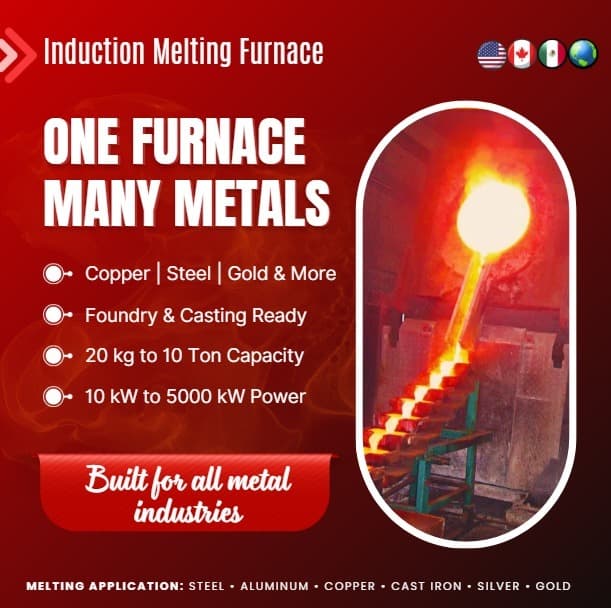

We are advisors and consultants to a wide range of industries—including Foundries, Steel Plants, Mining operations, Metal Mills, Universities, Military

institutions, Aerospace, and metal processing industry.

Our mission is to help clients reduce energy consumption and identify the most efficient induction furnace solutions ailored to their specific perational needs

Aluminum, a versatile and widely used metal, plays a crucial role in various industries, from aerospace to automotive. To transform raw aluminum into the desired forms for these applications, it demands cutting-edge technology for its production. Aluminum melting furnaces have emerged as the linchpin in this process, and in this comprehensive article, we will delve into their significance, working principles, and how they cater to the demand for aluminum in today’s industrial landscape.

Aluminum melting furnaces are specialized equipment designed to heat raw aluminum to its melting point, allowing it to be cast into various shapes and forms. These furnaces are crucial for industries that rely on aluminum, as they provide an efficient and controlled way to work with this valuable material.

Aluminum melting furnaces are pivotal in the initial phase of aluminum production, where raw aluminum scrap or ingots are transformed into a molten state.

This molten aluminum serves as the precursor for a myriad of applications, including automotive components, aerospace materials, construction supplies, and consumer goods.

Aluminum melting induction furnaces, a specific type of melting furnace, are known for their energy efficiency.

They use electromagnetic induction to heat the aluminum, which significantly reduces energy consumption and minimizes greenhouse gas emissions.

When it comes to working with aluminum, the advantages of using aluminum melting furnaces are evident:

These furnaces reduce energy consumption, making them a cost-effective choice for aluminum processing plants.

Aluminum melting furnaces ensure that the metal is melted uniformly and accurately, meeting the specific requirements of each application.

With minimal emissions and reduced waste, aluminum melting furnaces support environmentally friendly practices.

Aluminum induction furnaces require less maintenance compared to traditional methods, saving both time and resources.

Aluminum melting furnaces, particularly induction furnaces, operate on the principle of electromagnetic induction. Here’s how it works:

Aluminum melting furnaces are the backbone of the aluminum industry, enabling the efficient and precise transformation of raw aluminum into valuable products. As industries continue to demand high-quality aluminum products, the innovation and efficiency of these furnaces will play a vital role in meeting these requirements. Whether it’s for aerospace, automotive, or any other industry relying on aluminum, these furnaces provide the technology needed to shape the future with this remarkable metal. Incorporating primary and secondary keywords throughout this article, we have covered essential information about “Aluminum Melting Furnaces,” including details on “aluminum melting induction furnaces” and “aluminum induction melting furnaces.” By highlighting the benefits and working principles of these furnaces, we’ve provided a comprehensive guide for readers seeking knowledge in this field.

References