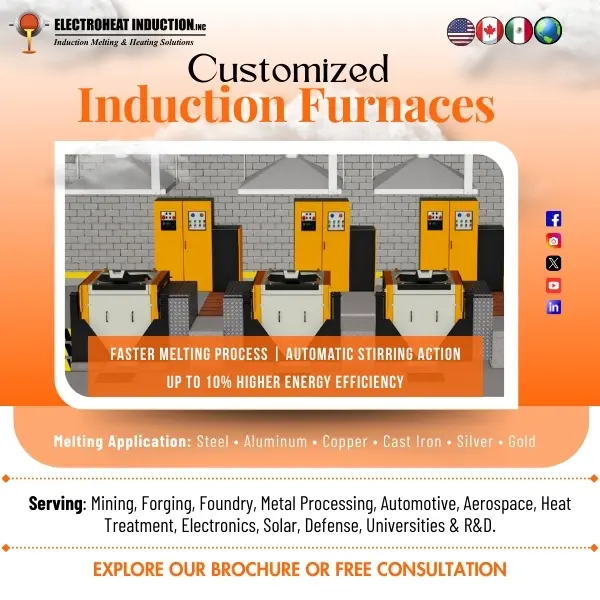

We are advisors and consultants to a wide range of industries—including Foundries, Steel Plants, Mining operations, Metal Mills, Universities, Military

institutions, Aerospace, and metal processing industry.

Our mission is to help clients reduce energy consumption and identify the most efficient induction furnace solutions ailored to their specific perational needs

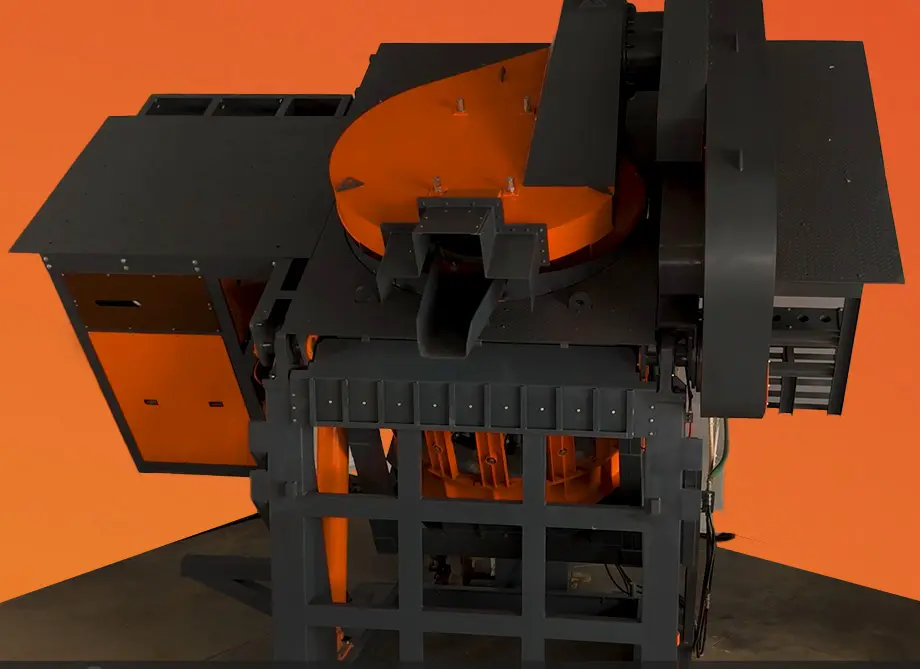

An induction holding furnace is essential equipment designed to maintain molten metal at a precise temperature after melting, optimizing conditions for casting. It is used across steel manufacturing, aluminum processing, and non-ferrous alloy production, providing a stable supply of molten metal at the desired casting temperature. This furnace uses electromagnetic induction to heat the metal directly, offering energy savings compared to re-melting, enhanced quality control through temperature management, and streamlined casting processes. Maintaining molten metal at a consistent temperature minimizes fluctuations and prevents oxidation—crucial for high-quality castings. By eliminating repeated melting cycles, induction holding furnaces reduce energy consumption, operational costs, and environmental impact.

Unlike melting furnaces that convert solid metal into liquid, induction holding furnaces are engineered to maintain molten metal at a consistent, pre-set temperature. Functioning as a thermal reservoir, these furnaces ensure steady supply for downstream operations like continuous or die casting. Also known as metal holding furnaces or coreless holding furnaces, they safeguard metallurgical integrity, minimize oxidation, and maintain temperature uniformity—factors essential to high-quality casting.

The operational principle is electromagnetic induction: an alternating current flows through copper coils surrounding a crucible, producing a magnetic field. This field induces eddy currents in the molten metal, generating heat within the metal itself. Unlike melting furnaces, holding systems only compensate for thermal losses—leading to lower energy use and reduced refractory wear.

Thermal insulation, smart temperature sensors, and high-quality crucibles enhance retention. Whether it’s an induction holding furnace for aluminum or for steel, each is configured based on the metal’s thermal characteristics, ensuring precise control and continuous casting stability.

Induction holding furnaces maintain molten metal temperature without hot or cold spots, preventing alloy segregation.

Heat is generated only as needed to maintain temperature, reducing energy consumption significantly compared to full re-melting.

The absence of combustion eliminates smoke, dust, and harmful emissions, improving workplace safety.

A steady flow of molten metal ensures turbulence-free pouring, minimizing defects.

Supports continuous casting lines by eliminating delays from re-melting cycles.

In practical terms, the benefits of an induction holding furnace become even clearer when compared to traditional re-melting methods. While both systems are used to deliver molten metal for casting, their operation, efficiency, and impact on quality differ significantly.:

Induction holding furnaces are categorized into coreless, channel-type, and crucible-based systems, each offering specific benefits based on application requirements. Whether you’re dealing with ferrous or non-ferrous materials, choosing the right induction holding furnace type ensures optimal energy efficiency, thermal consistency, and casting performance. Below is a detailed comparison of these furnace types to help engineers, foundry operators, and industrial buyers make informed decisions.

Furnace Type | Structure | Best Suited For | Key Advantages | Limitations |

Coreless Induction Holding Furnace | Non-magnetic refractory crucible surrounded by copper coil with direct induction heating | Small to medium batch operations and diverse alloy types | Fast heat-up, excellent temperature control, and alloy flexibility | Higher heat loss than channel-type; less suitable for continuous large-volume operations |

Channel-Type Induction Holding Furnace | Molten metal bath connected to induction coil through a looped or U-shaped channel | Large-scale continuous casting; steel and heavy non-ferrous applications | Efficient heat retention, continuous operation, and natural stirring action | More complex structure; limited flexibility for alloy switching |

Crucible-Based Holding Furnace | Molten metal held in a fixed or replaceable crucible with internal coil arrangement | Aluminum die casting and non-ferrous metal holding where cleanliness is critical | Minimal oxidation, precise temperature holding, compact design | Lower holding capacity; less efficient for large-volume operations |

Table 2. Comparison of Induction Holding Furnace Types.

Induction holding furnaces are engineered to serve a broad range of metallurgical applications, each with unique thermal, chemical, and casting demands. Below is a breakdown of how these furnaces are applied based on the type of metal being processed:

Steel production requires tight temperature control to avoid variations in mechanical properties during casting. Induction holding furnaces are extensively used in continuous casting lines to maintain precise pouring temperatures, stabilize flow rates, and reduce casting defects such as shrinkage porosity or segregation.

Aluminum is highly sensitive to oxidation and hydrogen pickup at high temperatures. Induction holding furnaces provide a clean, controlled holding environment, ensuring molten aluminum remains at a stable temperature with minimal dross formation. This is especially vital in die casting, extrusion, and precision component manufacturing.

Non-ferrous foundries benefit from the efficient thermal retention and cleanliness of induction holding systems. These furnaces support the production of electrical components, plumbing fixtures, and high-performance bearings by minimizing oxide inclusions and ensuring uniform alloy distribution.

Selecting the right induction holding furnace involves evaluating several configuration factors that directly impact furnace performance, energy efficiency, and casting quality. These considerations are especially important in high-throughput environments such as steel plants, aluminum casting lines, and non-ferrous foundries.

Below are the most critical parameters to assess when specifying or customizing an induction holding furnace system:

The choice of crucible material—graphite, alumina, magnesia—depends on the metal type and operating temperature. Furnace capacity should align with production demand: oversized crucibles waste energy, while undersized ones disrupt continuous casting.

Water-cooled coils are preferred for high-power applications due to superior thermal management. Air-cooled options are suitable for small- to mid-sized setups with lower duty cycles.

Coil geometry, copper turns, and solid-state inverters must match metal characteristics and heating profiles. Medium- to low-frequency power supplies are selected based on metal conductivity and melting point.

Advanced PID controllers, digital panels, and thermocouples enable accurate monitoring and temperature stability. This precision minimizes thermal fluctuations and enhances product consistency.

Options include tilting, bottom pouring, and stopper rods. Selection depends on desired flow control, mold access, and contamination sensitivity.

Efficient foundries rely on automated integration between melting, holding, and casting systems. Features such as synchronized melting, auto transfer, and smart monitoring allow seamless production flow.

To further simplify the selection process, the table below outlines key configuration features and their practical relevance:

Configuration Feature | Description |

Holding Capacity | Available from 3 Tons to 100 Tons, scalable to production volume |

Power Range | Power options range from 300 kW to 8000 kW, adaptable to metal type and batch size |

Furnace Structure | Available in Steel Shell or Steel Frame construction for durability and load support |

Metal Compatibility | Suitable for ferrous and non-ferrous metals including aluminum, steel, and copper alloys |

Pouring Mechanism | Equipped with automated or tilting pouring systems for efficient mold feeding |

Temperature Control System | Digital controllers and thermocouples enable auto temperature regulation |

Molten Heat Requirement | No additional molten heat input required—retains existing thermal state |

Furnace Lid | Rotating furnace lid minimizes heat loss and allows safe charging |

Construction Quality | Rugged, industrial-grade construction for long-term reliability in harsh conditions |

Automation Integration | Optional PLC, SCADA, and IoT-based systems for smart monitoring and control |

Table 3. Key Configuration Features for Induction Holding Furnaces.

Induction holding furnaces are indispensable in modern metal casting, offering unmatched precision in temperature control, energy efficiency, and casting quality. Their application spans steel, aluminum, and non-ferrous industries—making them essential for continuous casting and smart foundry operations. As technology advances, these furnaces are increasingly equipped with automation and IoT capabilities, enabling real-time optimization and predictive maintenance. Explore Electroheat Induction’s full range of induction holding furnace solutions engineered for high performance and seamless integration.